Virtual trade show

|

Automation

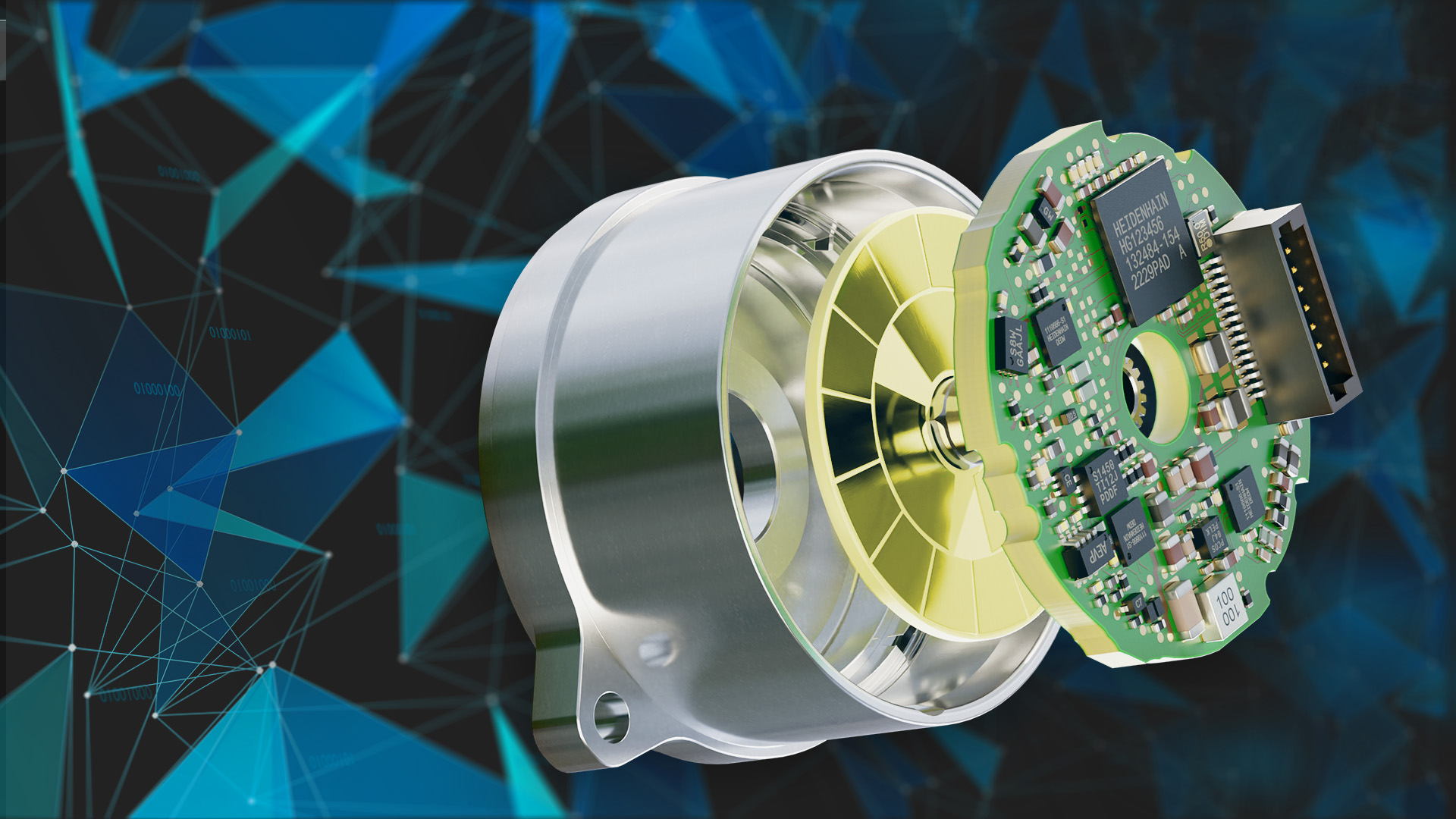

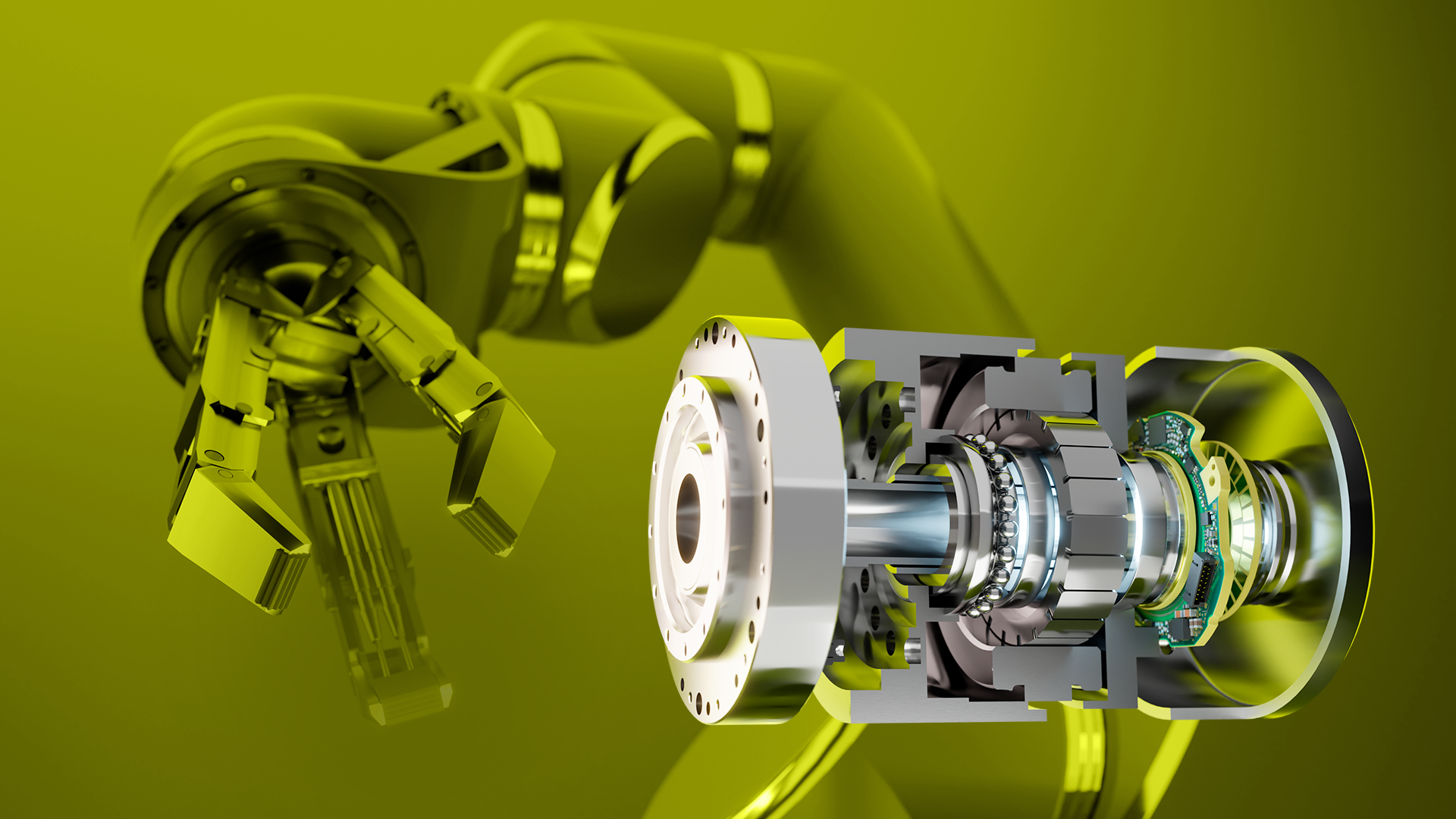

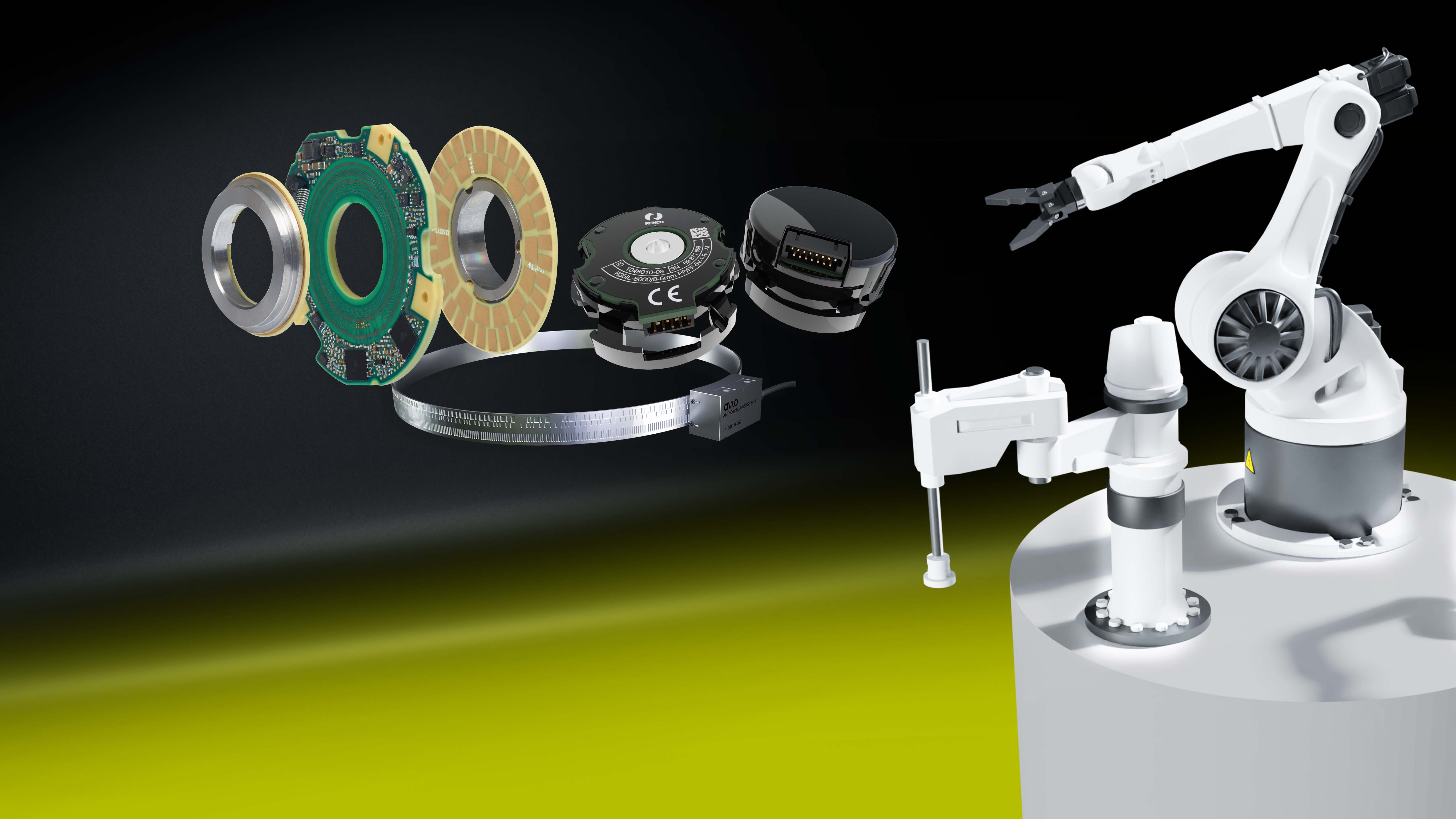

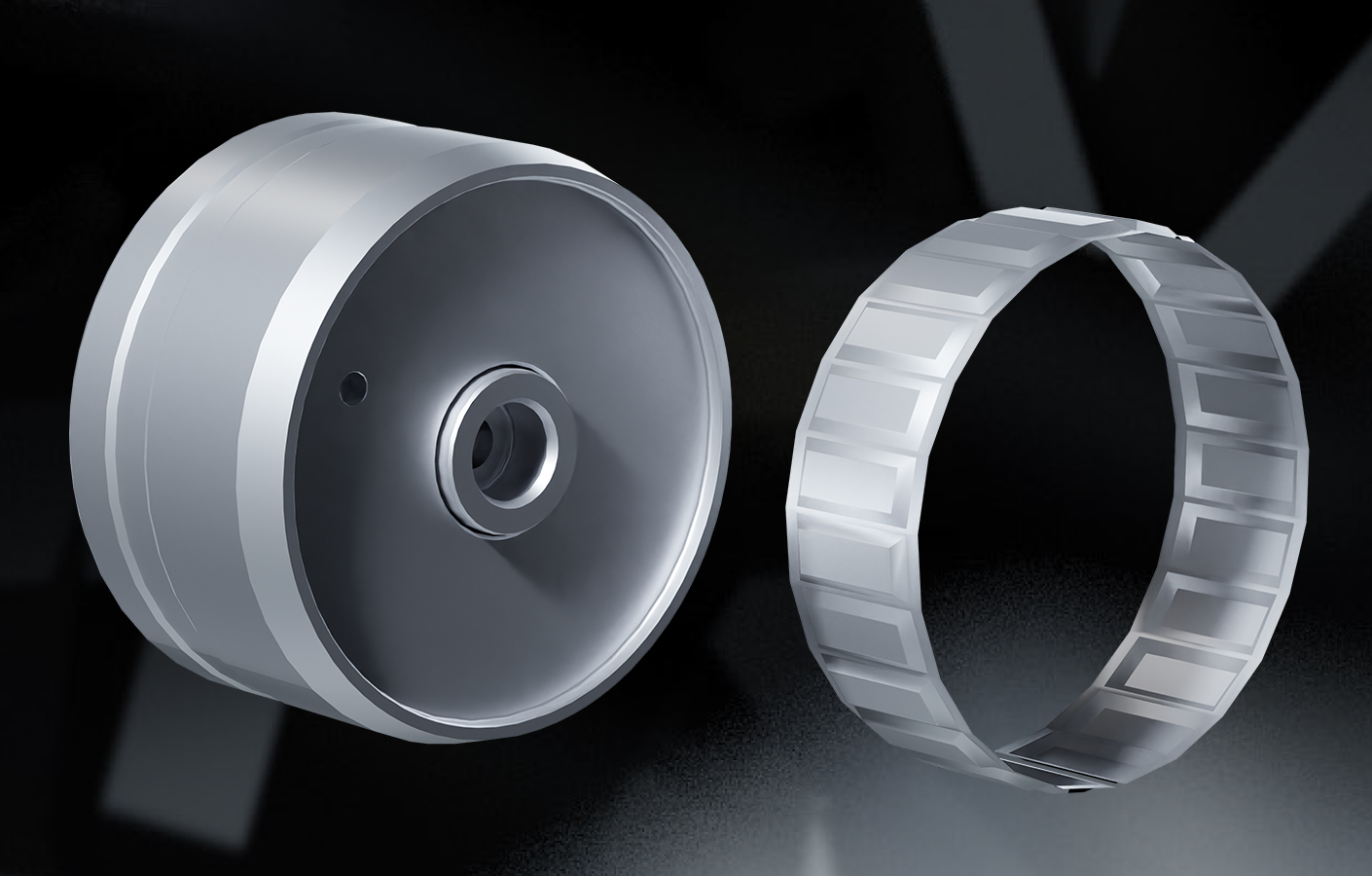

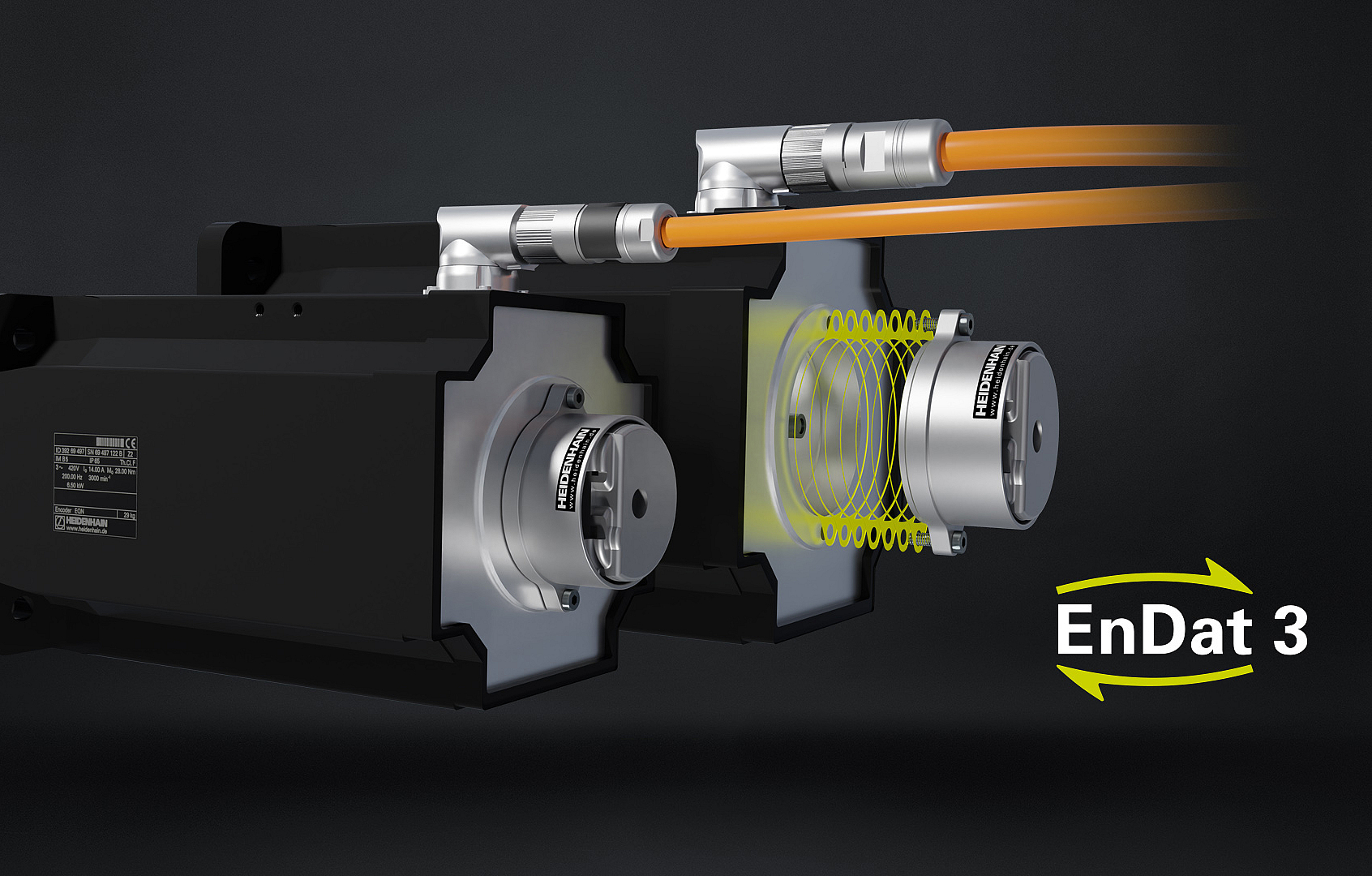

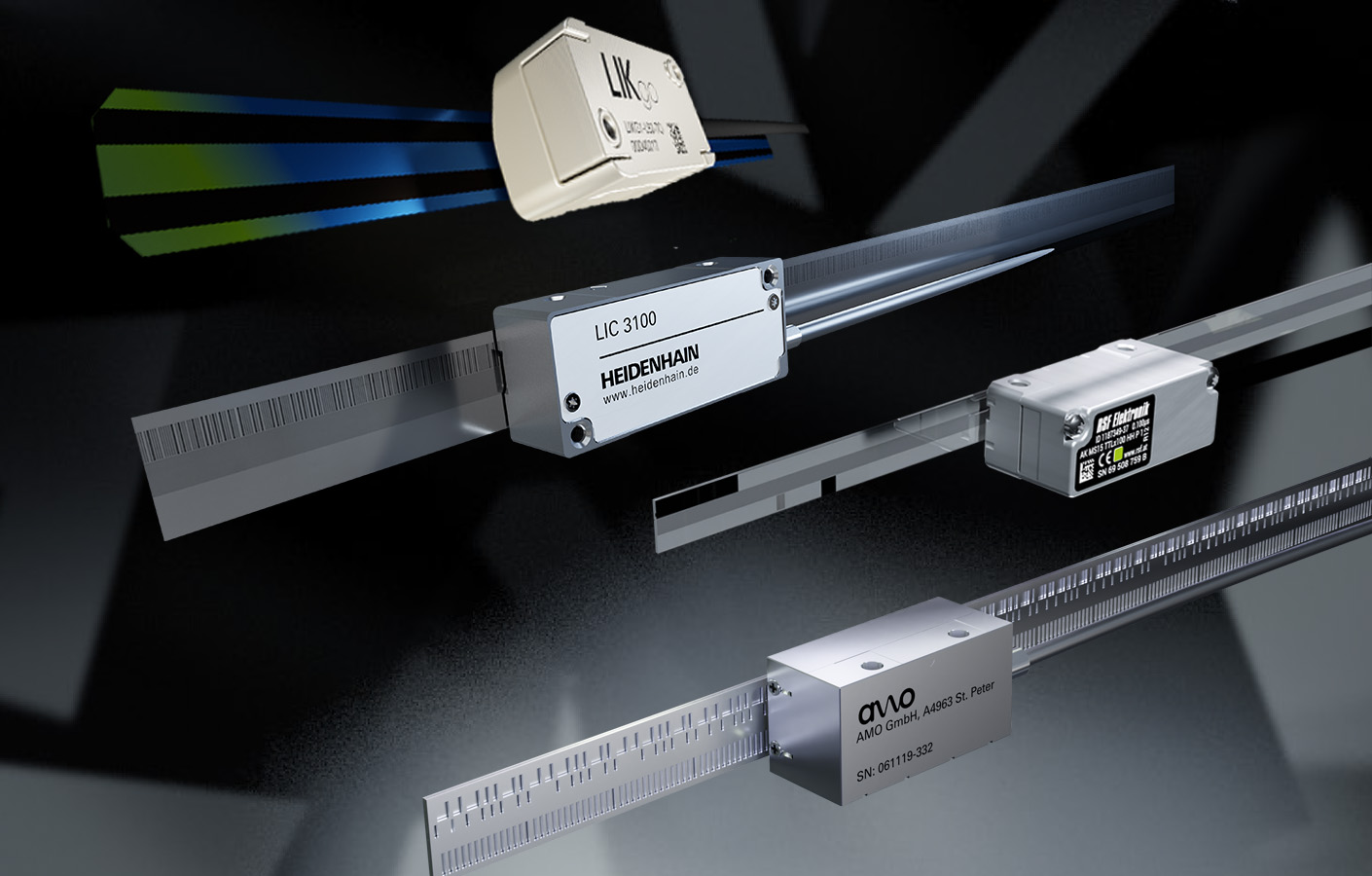

Improve the accuracy of your robots and enable collision monitoring in cobots by using two position feedback encoders: a motor encoder on the motor output shaft and a secondary encoder on the gearbox output shaft. In this video, a cobot demo unit successfully performs a force measurement of 100 Nm without torque sensors. This is the critical force to be monitored when a cobot collides with the human body.