Empower Productivity

The right encoders for every robotics and automation challenge

The HEIDENHAIN GROUP is your one-stop provider for rotary encoders, angle encoders, and linear encoders for the full range of standard to high-end applications.

Improve the productivity, reliability, and accuracy of your machines with motion-feedback solutions from HEIDENHAIN, AMO, RENCO, and RSF.

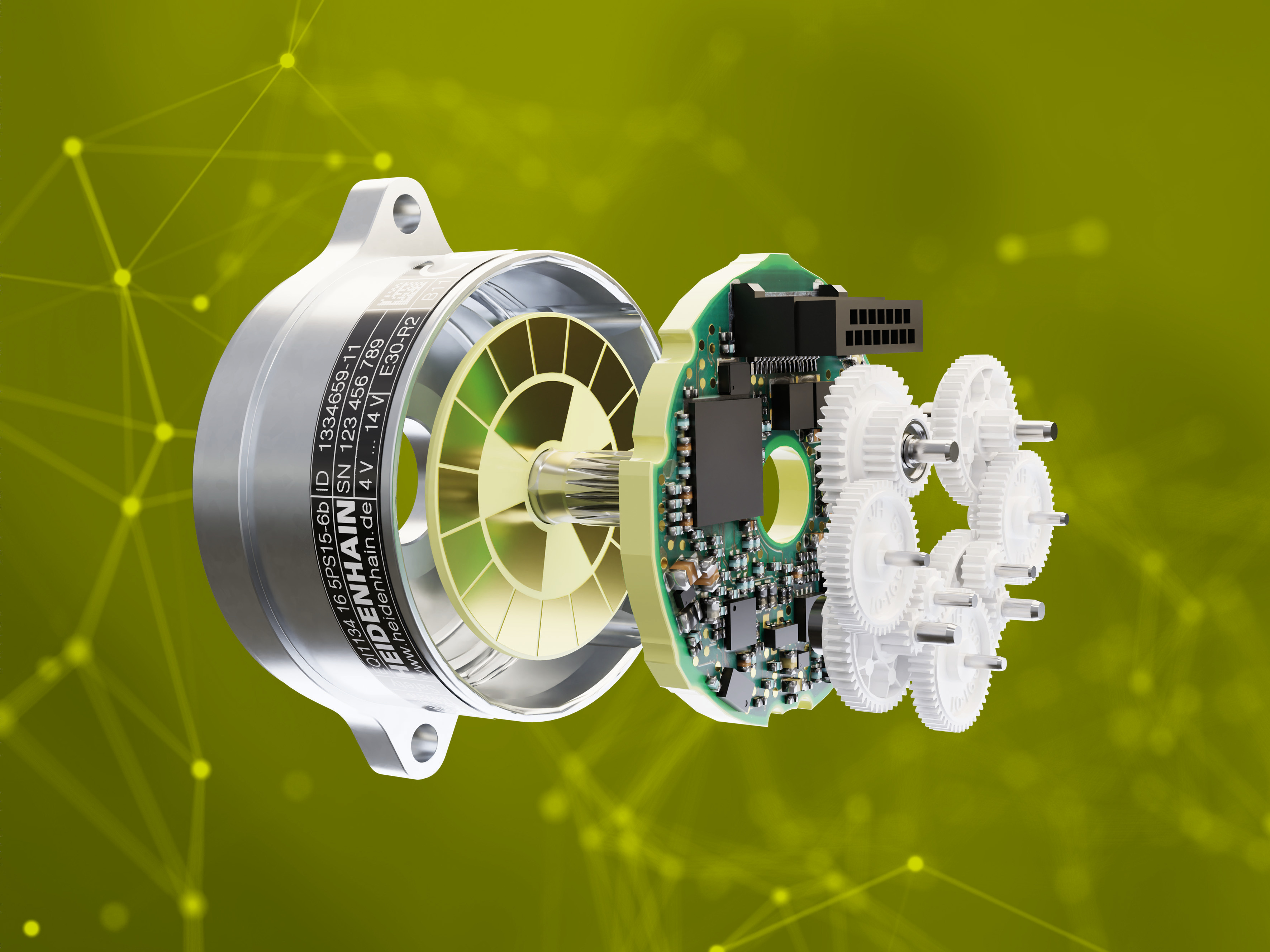

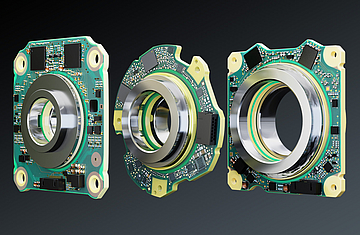

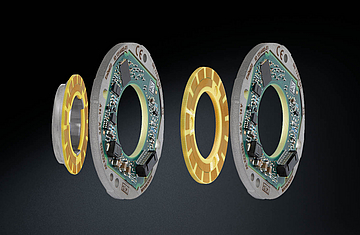

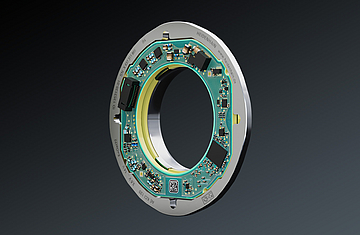

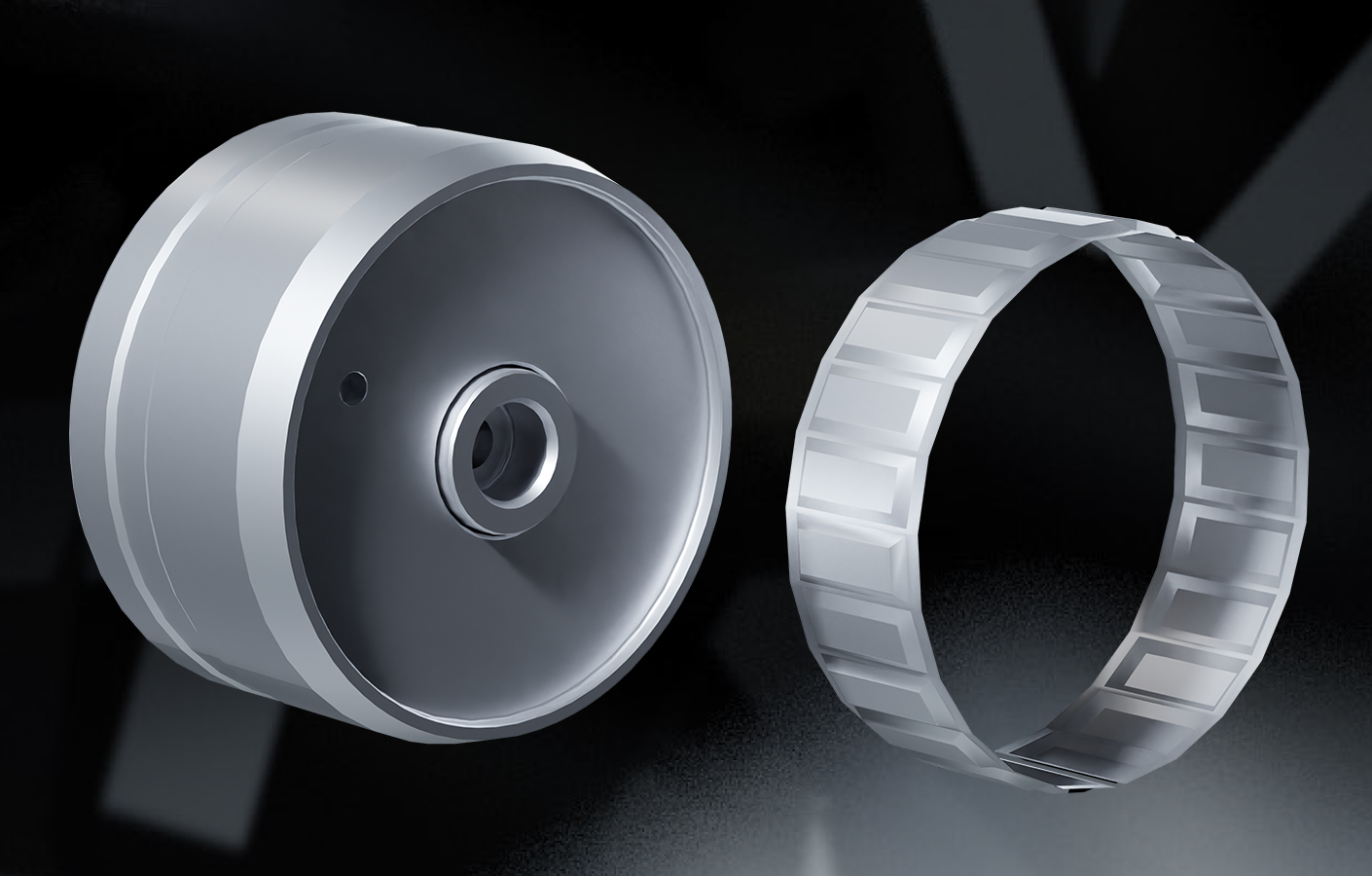

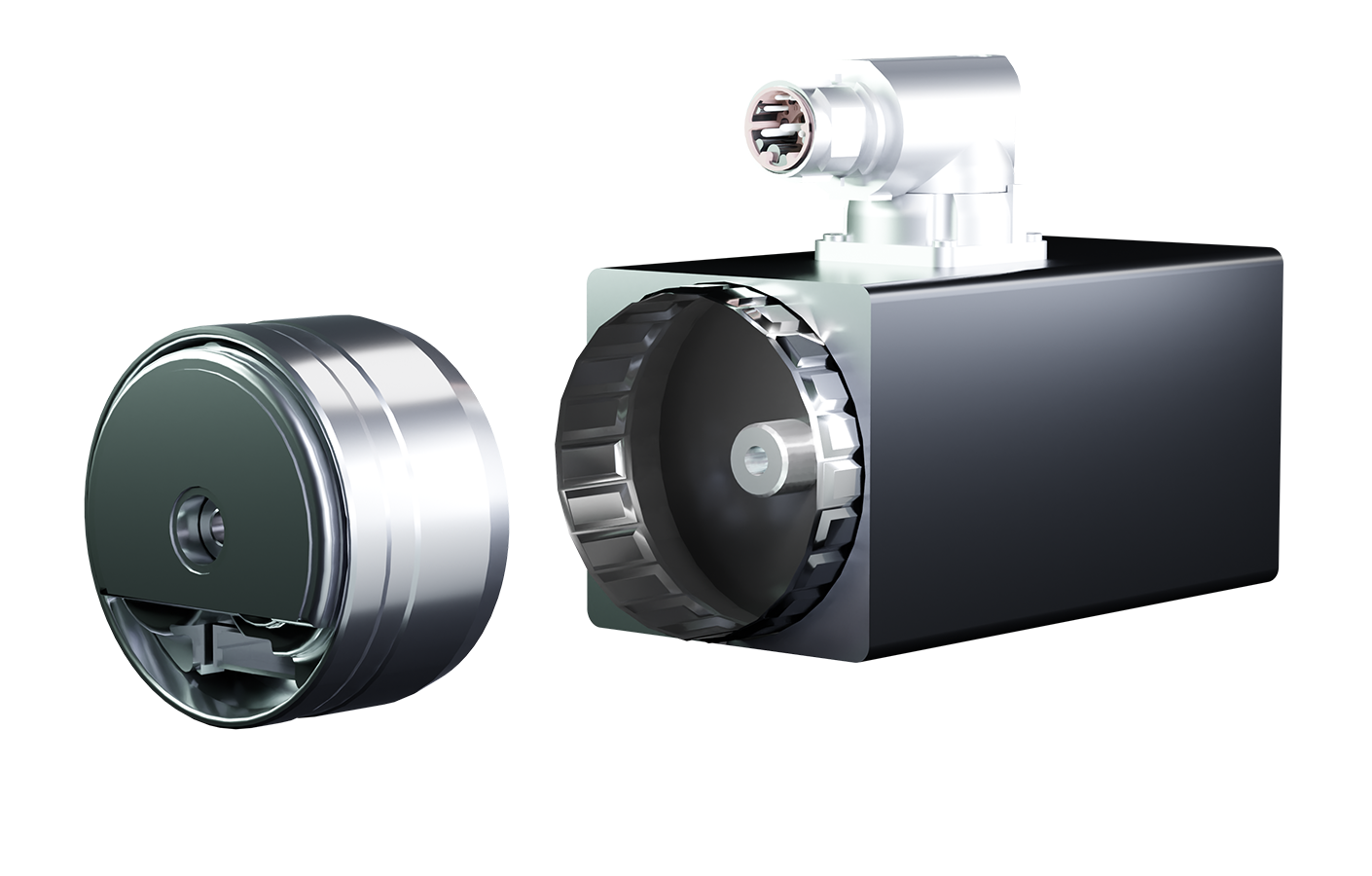

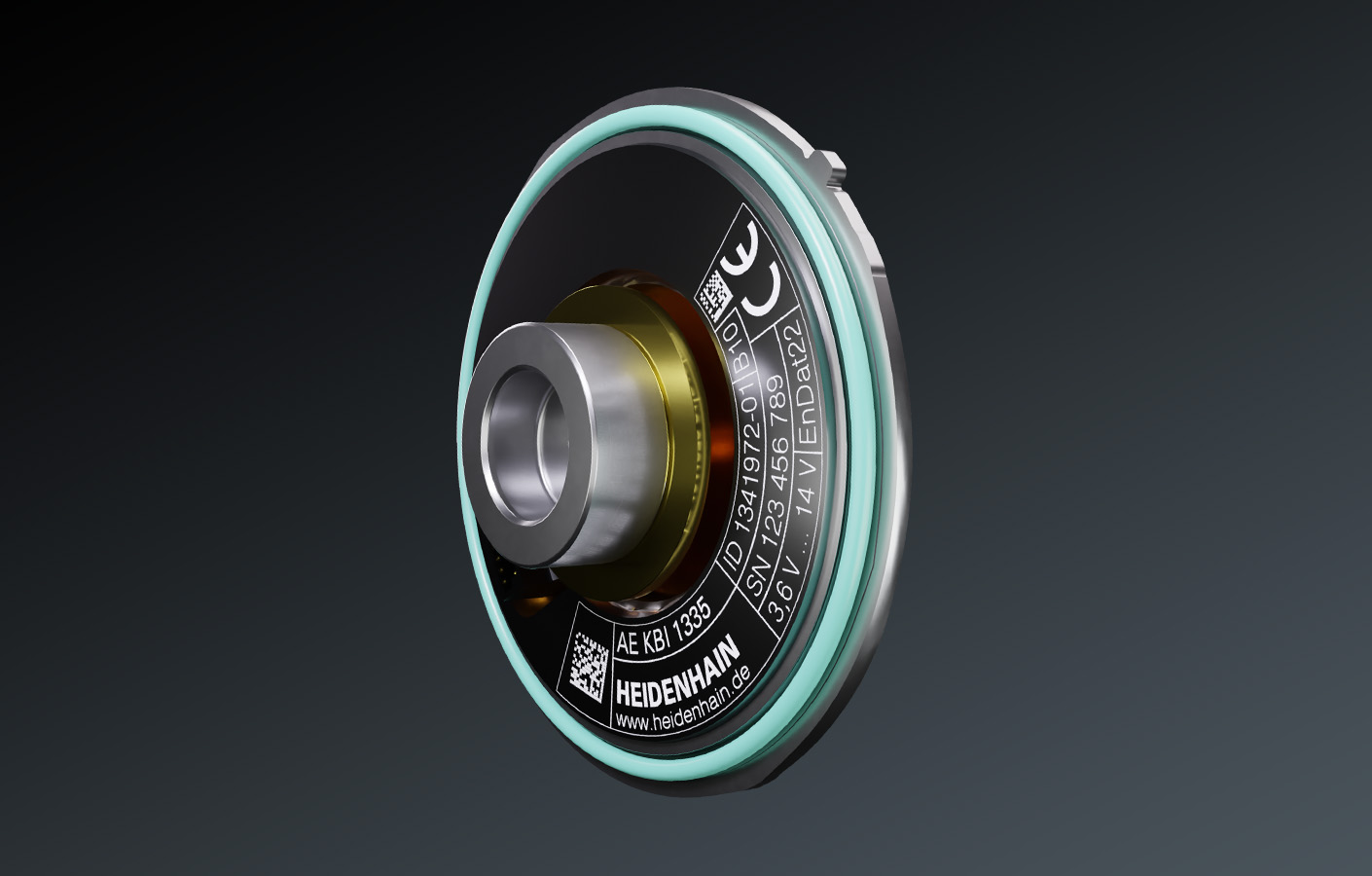

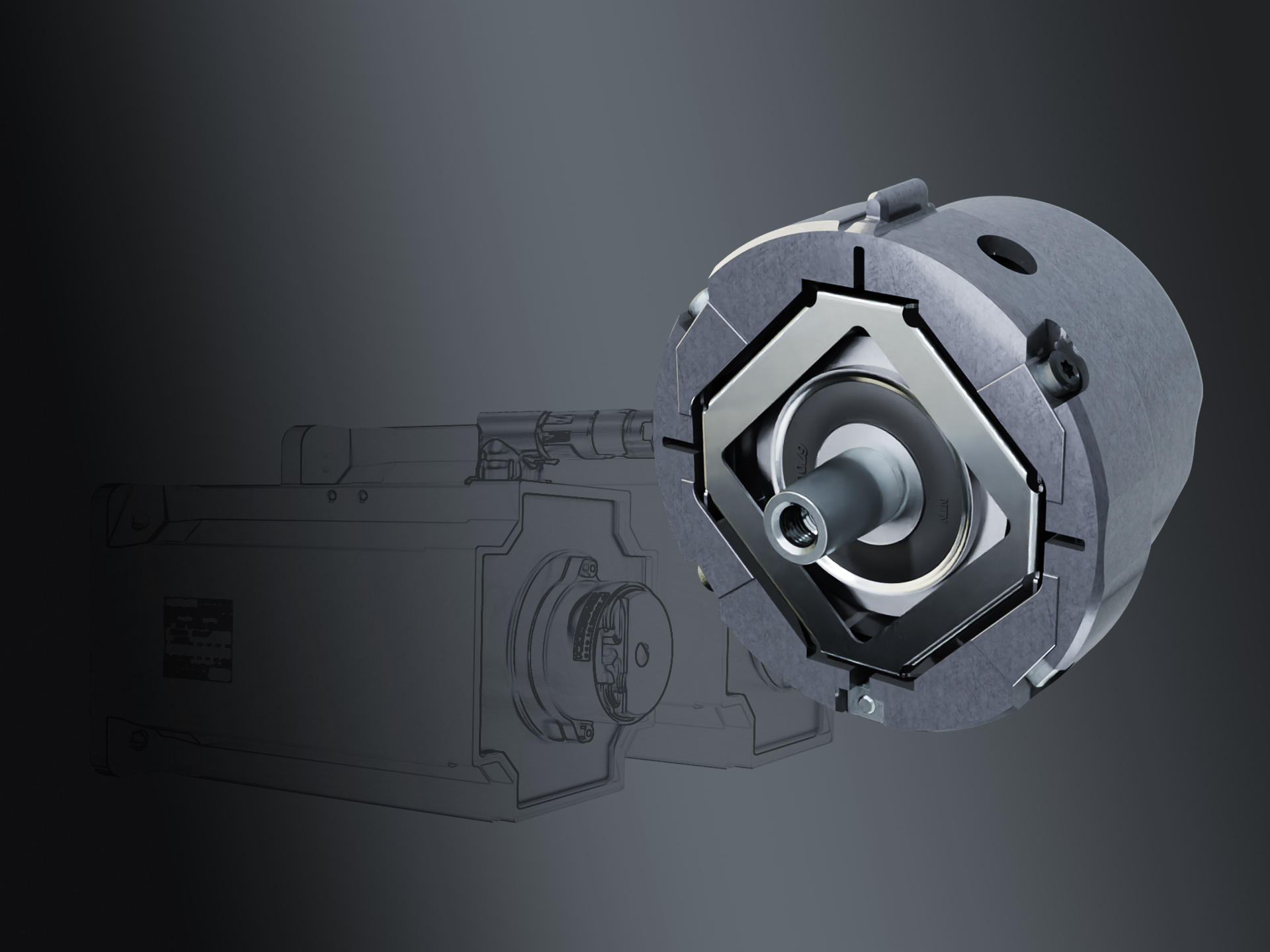

ECI 1323 Splus and EQI 1335 Splus

Rotary encoders with built-in vibration analysis

Featuring a built-in accelerometer, the HEIDENHAIN ECI 1323 Splus and EQI 1335 Splus inductive rotary encoders deliver position feedback and vibration analysis on rotating machine elements. By detecting and analyzing critical vibrations early on, the new encoders supports online condition monitoring in high-wear automation systems.

For even more condition data, the ECI 1323 Splus and EQI 1335 Splus supports up to three connected external temperature sensors. The EnDat 3 interface handles all data transmission to downstream electronics. Thanks to its added functionality, the Splus encoders saves on additional sensors, reduces cabling and makes installation easier.

Empower Productivity

The right encoders for every robotics and automation challenge

The HEIDENHAIN GROUP is your one-stop provider for rotary encoders, angle encoders, and linear encoders for the full range of standard to high-end applications.

Improve the productivity, reliability, and accuracy of your machines with motion-feedback solutions from HEIDENHAIN, AMO, RENCO, and RSF.