Empower Productivity

The right encoders for every robotics and automation challenge

The HEIDENHAIN GROUP is your one-stop provider for rotary encoders, angle encoders, and linear encoders for the full range of standard to high-end applications.

Improve the productivity, reliability, and accuracy of your machines with motion-feedback solutions from HEIDENHAIN, AMO, RENCO, and RSF.

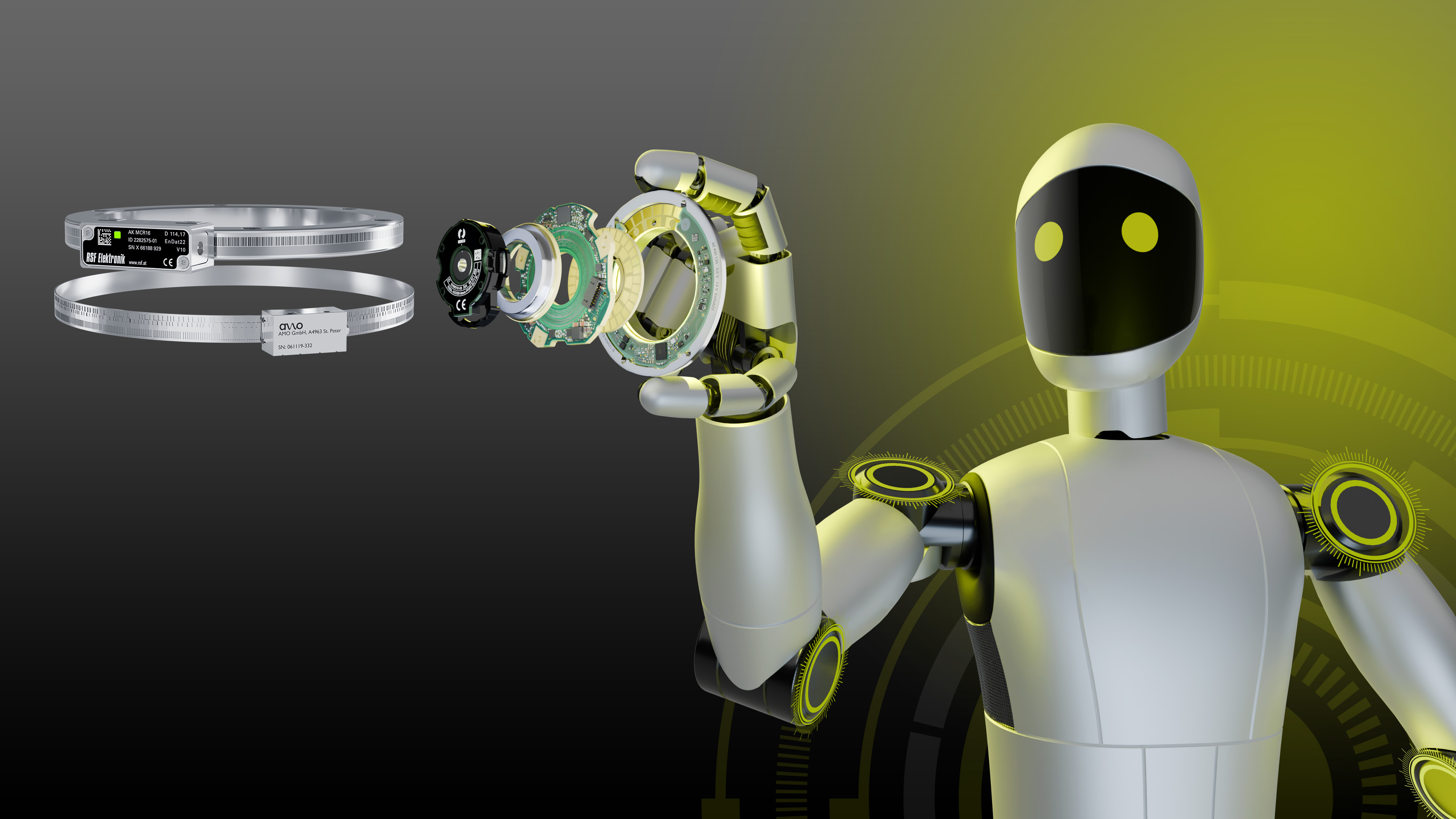

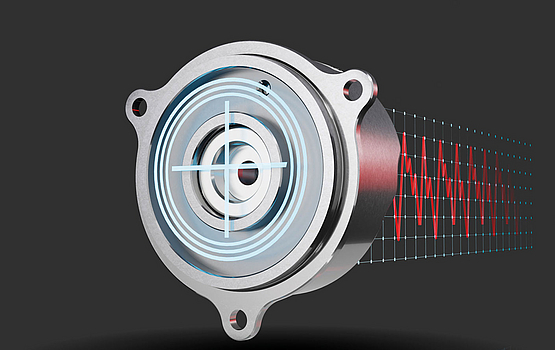

More accuracy and reliability for cobots:

secondary encoders for collision monitoring

Detect critical vibrations and collect temperature data.

Gain improved accuracy and maximum process reliability.

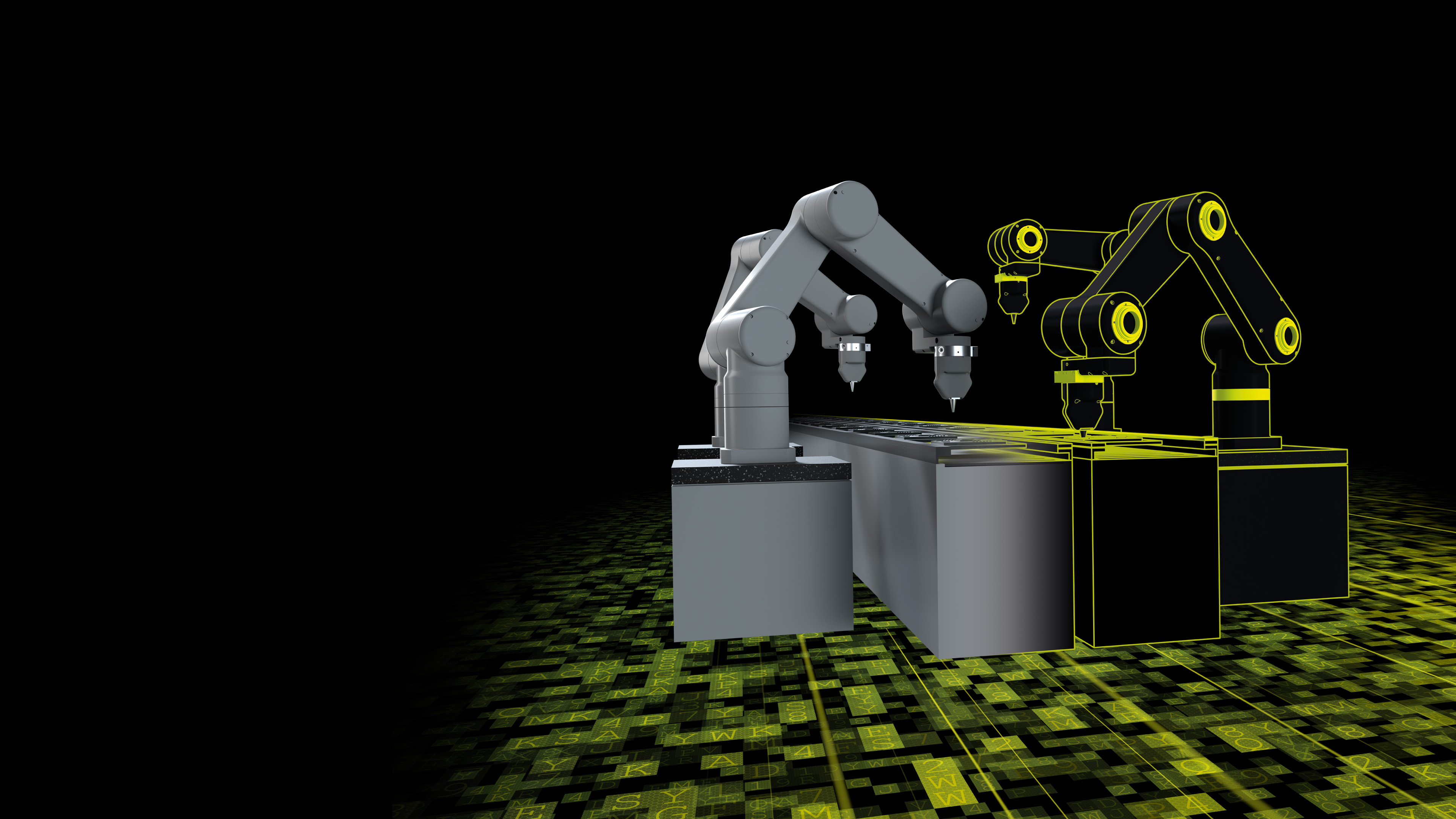

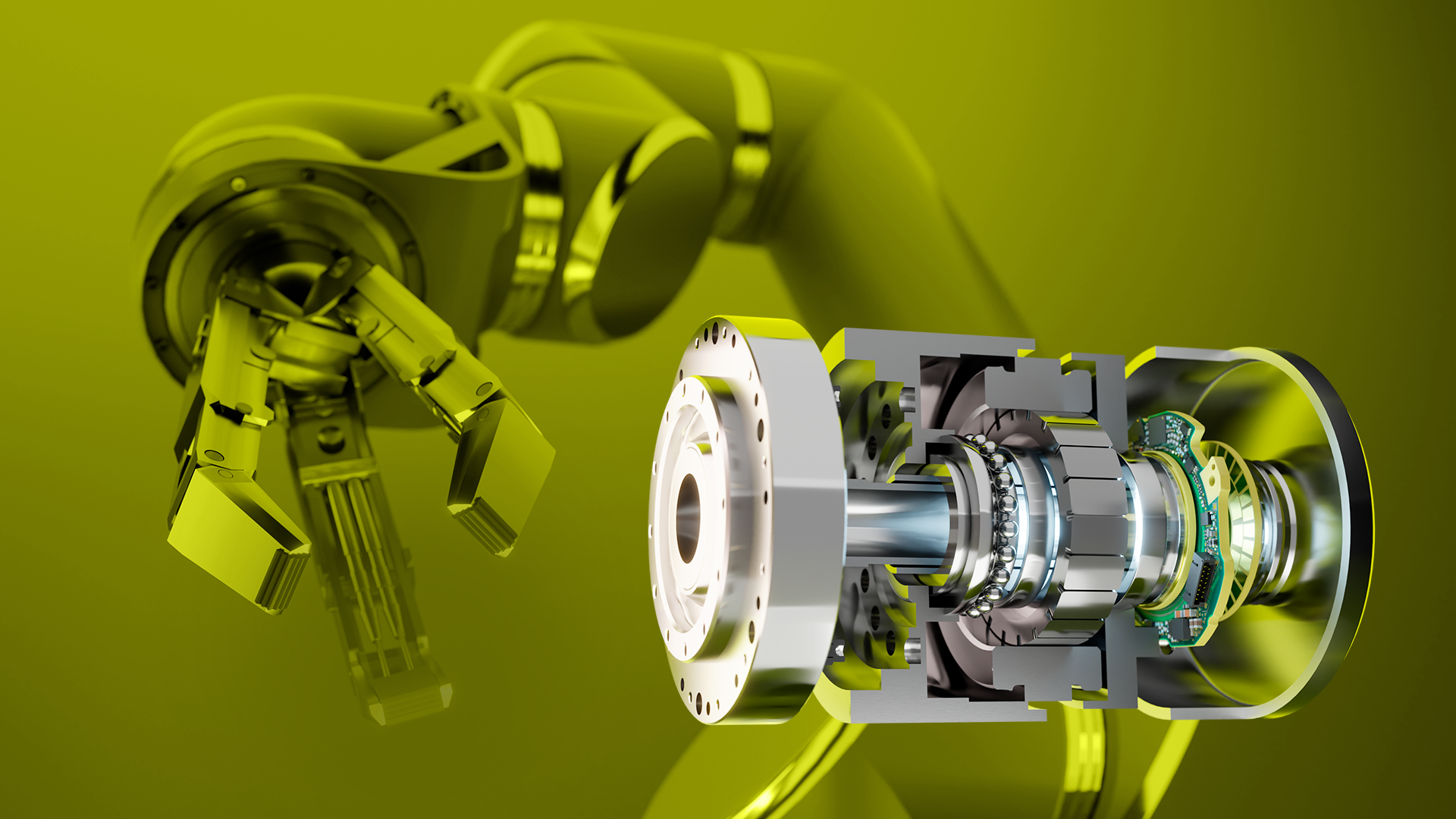

Advanced robotics

Rotary encoders with added functionality are enabling new capabilities and highly demanding applications for robots. Dual encoders and secondary encoders from the HEIDENHAIN CORPORATE GROUP improve tool-center-point accuracy and allow cobot designers to implement collision monitoring.

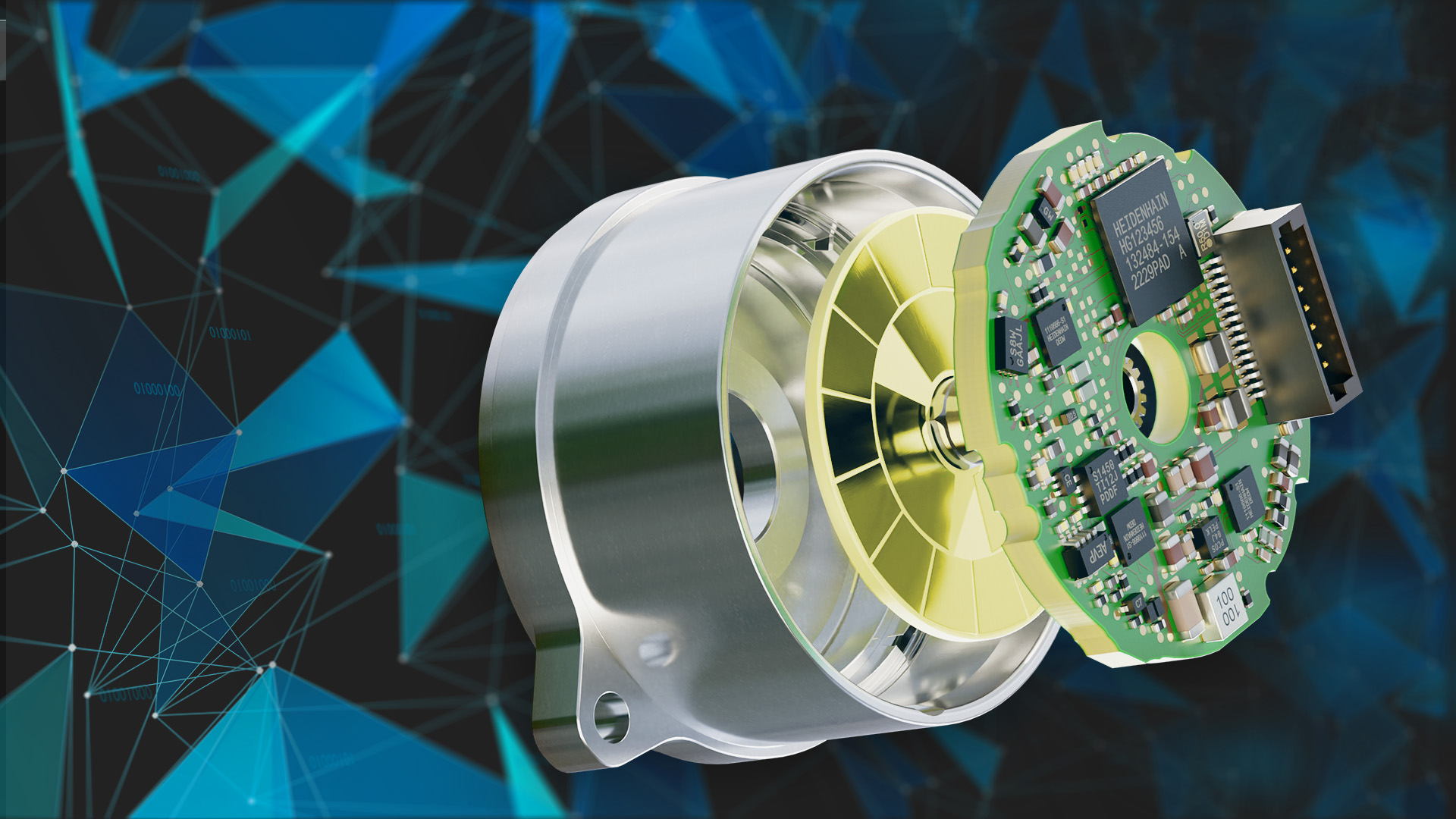

More than position feedback

Leverage intelligent rotary encoders to monitor your machines in demanding automation applications. The ECI 1323/1335 Splus rotary encoders feature a built-in accelerometer that detects vibrations, enabling you to plan maintenance intervals based on valid operating data.

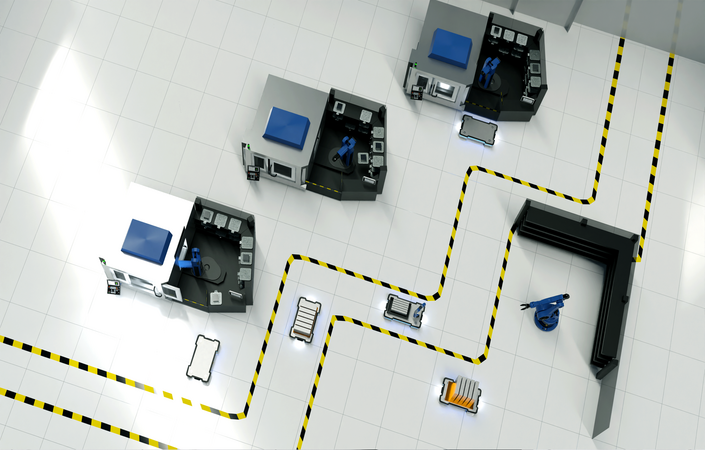

System integration with EnDat

EnDat is a data interface from HEIDENHAIN for digitalizing your motion control and automation solutions. This future-ready interface makes it easy to dependably integrate encoders into your systems. The fast and intelligent data it delivers allows you to optimize the performance and reliability of your machines.

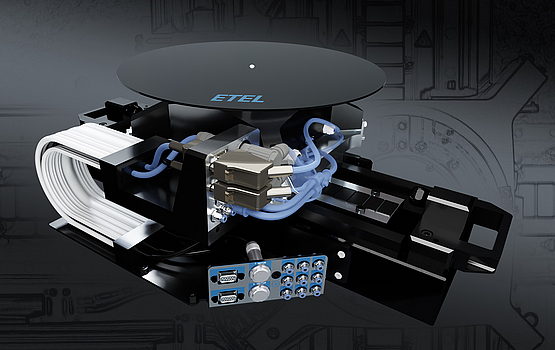

High-end motion systems

Due to the continual miniaturization of chips in front-end processes and ever denser PCBs in back-end manufacturing, the semiconductor and electronics industry places unique demands on automated production equipment. Solutions from HEIDENHAIN and ETEL deliver exceptional accuracy and performance.