Virtual trade show

|

Machine tool

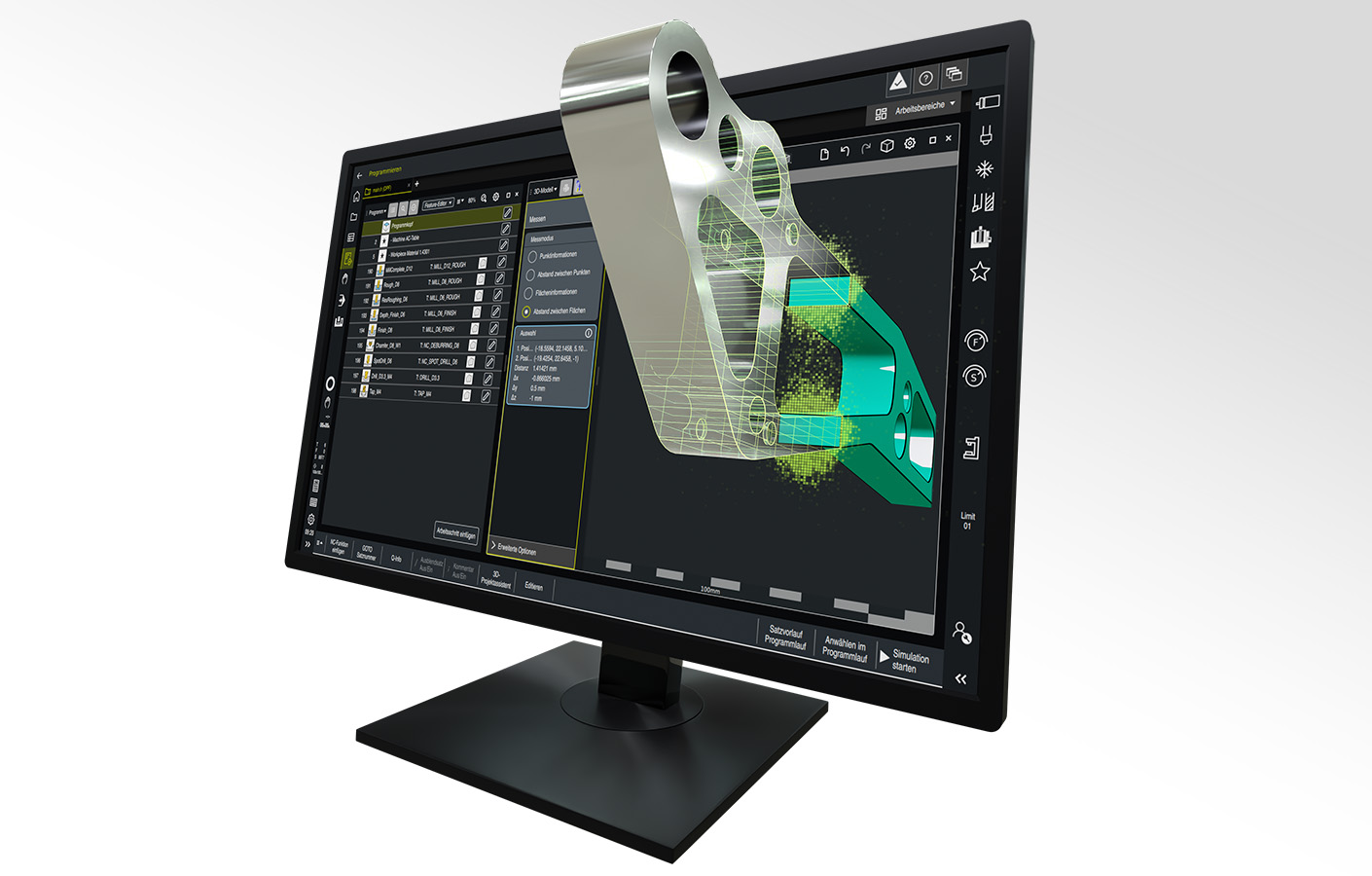

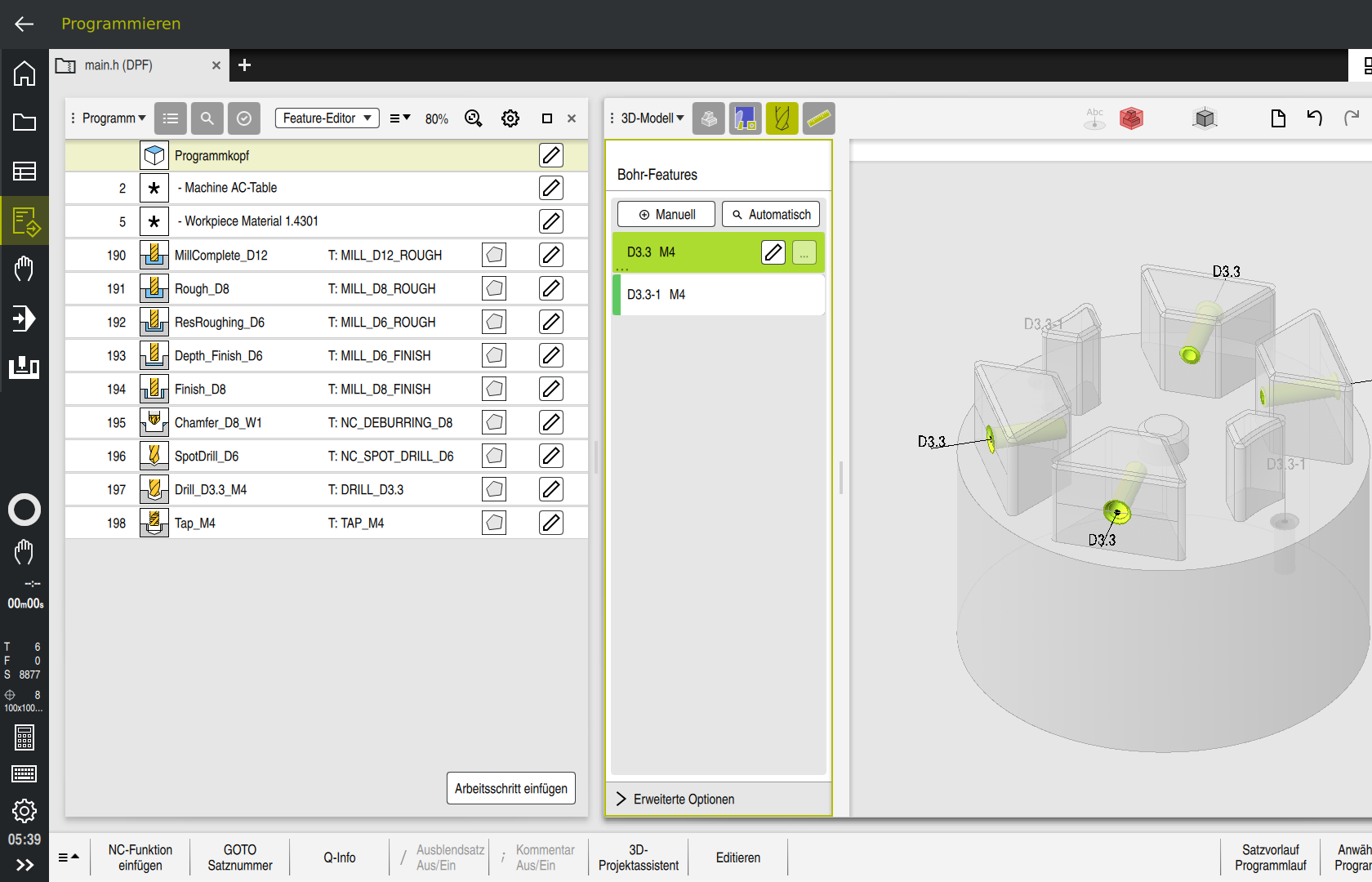

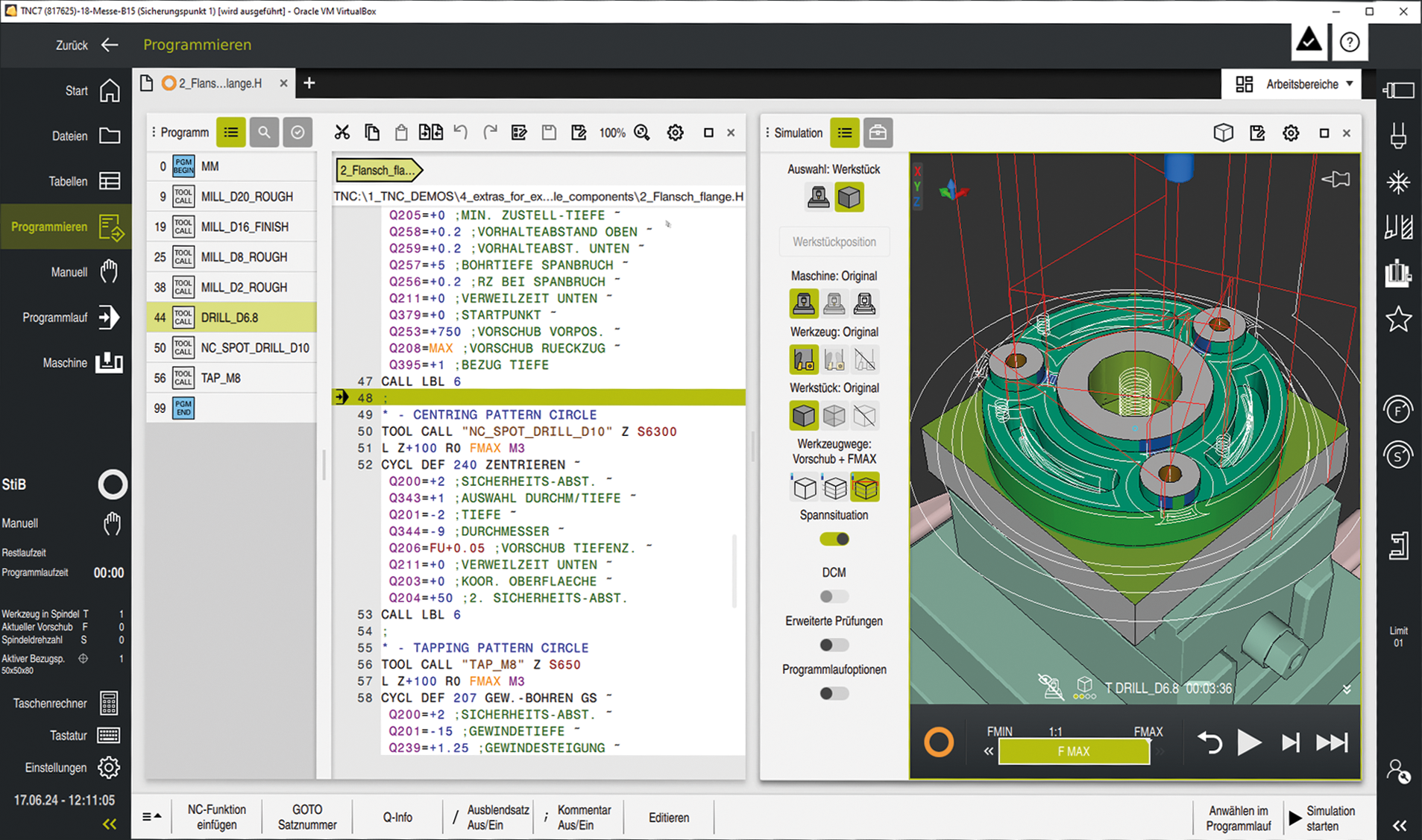

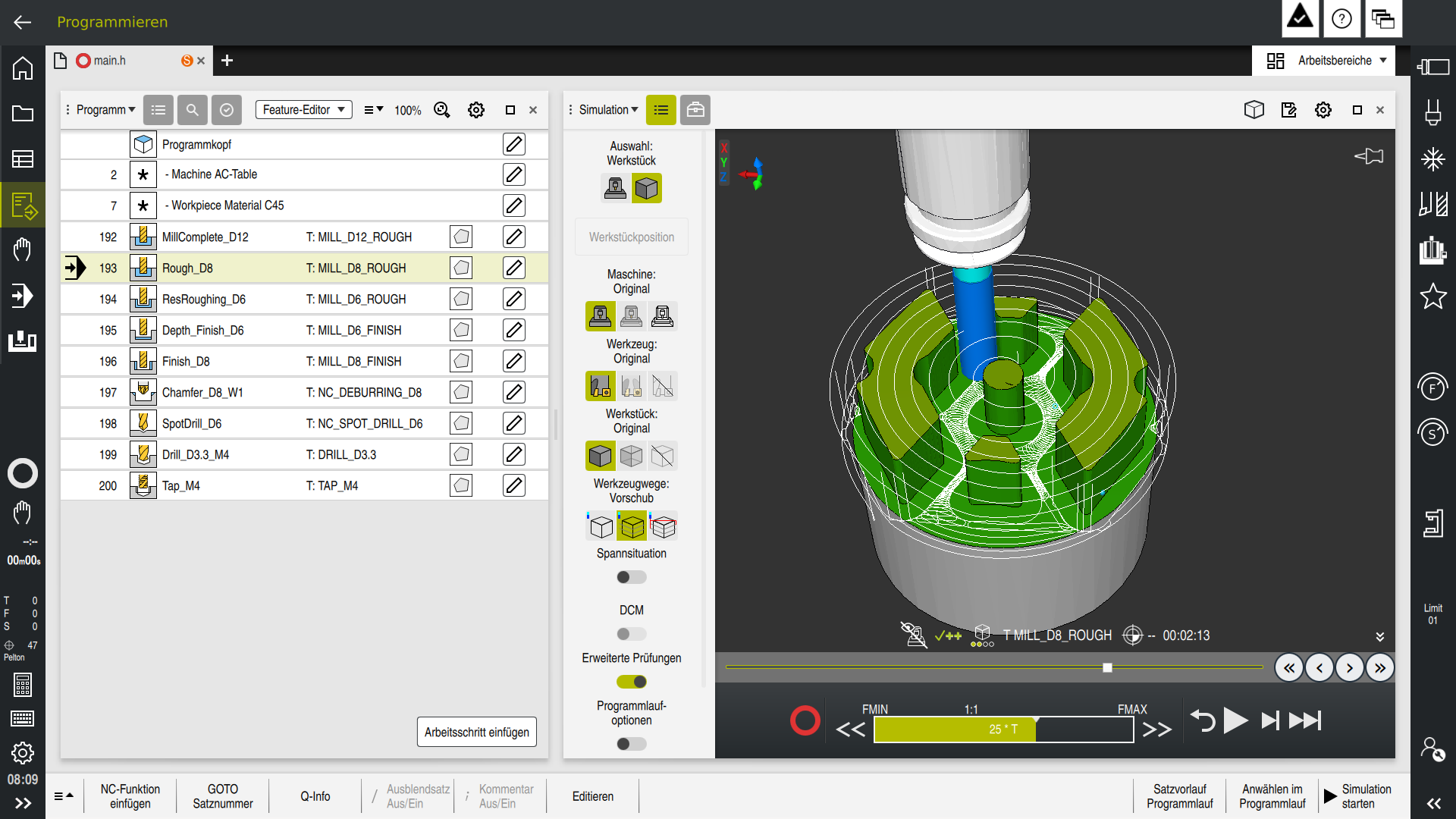

TNC7: Innovative | Sustainable | Dependable

Further developed to include four hardware variants and new done-in-one machining capabilities, the TNC7 continues to raise the benchmark for intuitive CNC operation and reliable shopfloor processes.

Discover intelligent and innovative solutions for agile and efficient manufacturing!

Empower Manufacturing: Intelligent system solutions

for machine tools and automated production processes

Discover exceptional accuracy, reliability, and performance through carefully engineered systems and perfectly matched components from the HEIDENHAIN GROUP. As a partner, we support you in achieving efficient, agile, and resilient manufacturing processes.