Empower Manufacturing: Intelligent system solutions

for machine tools and automated production processes

Discover exceptional accuracy, reliability, and performance through carefully engineered systems and perfectly matched components from the HEIDENHAIN GROUP. As a partner, we support you in achieving efficient, agile, and resilient manufacturing processes.

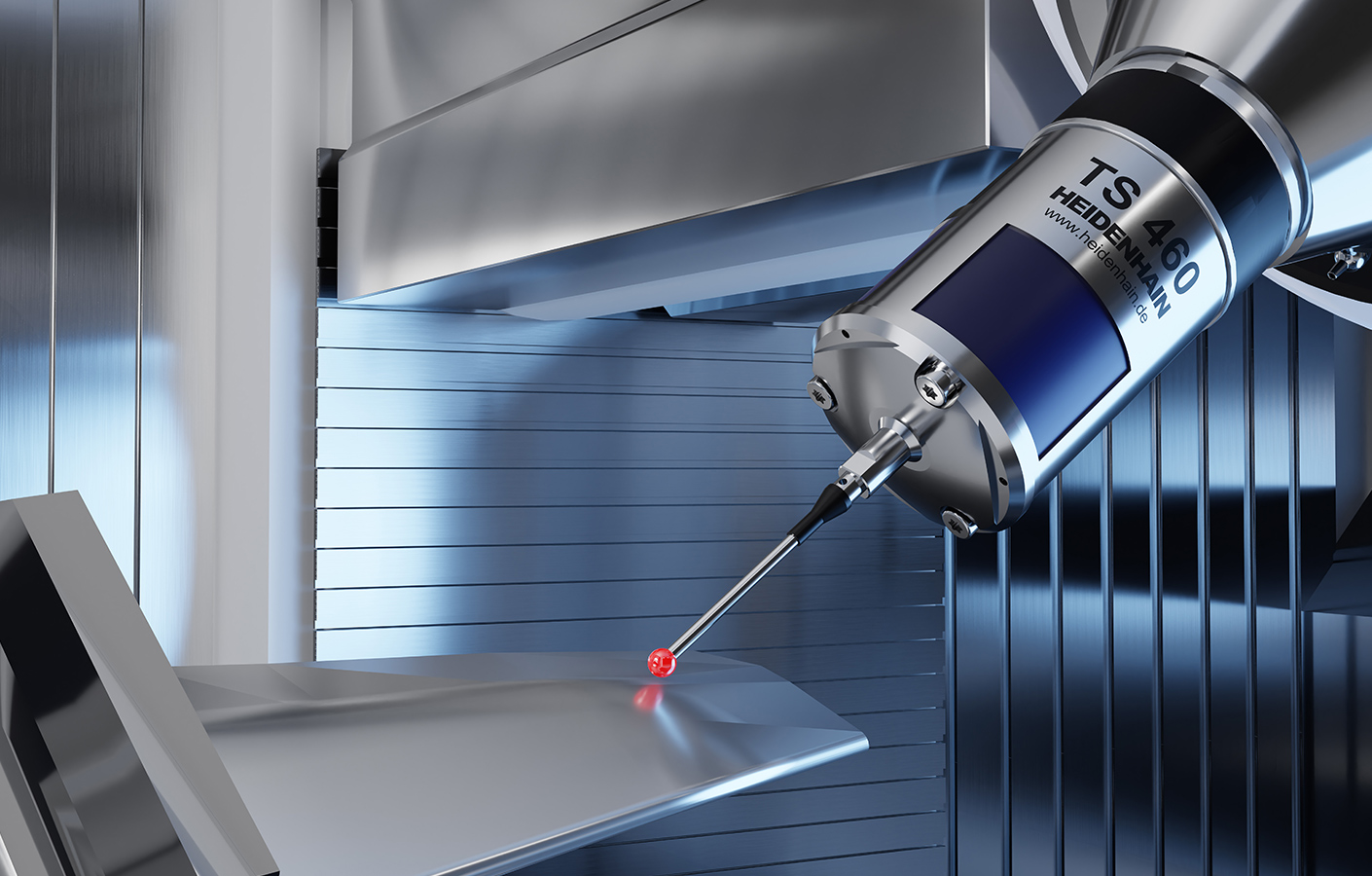

TNC7: New functions for

done-in-one machining

Cylindrical grinding, shaping and cylinder surface machining will be joining the repertoire of TNC7 controls, thereby rounding out their done-in-one milling, turning and grinding capabilities. Cylinder surface machining will also be available for users of the TNC7 basic.

The new TNC7 go for training

and machine upgrades

Debuting at EMO 2025, the TNC7 go brings the intuitive, future-ready TNC7 user interface to vocational training centers and legacy machines. As a straight-cut control, the TNC7 go is the next-generation successor to the HEIDENHAIN TNC 128. A particular highlight is its new “Graphical positioning” function.

Debut of the vTNC7

programming system with AI

With an AI chatbot and other innovative functions, the new vTNC7 software for PCs is taking NC program creation and tasked-focused user support to a new level. With Feature-Based Programming, users can automatically create Klartext programs based on CAD data from 3D models. The new Klartext Converter then allows these programs to run on pre-TNC7 HEIDENHAIN controls that lack the required software options.

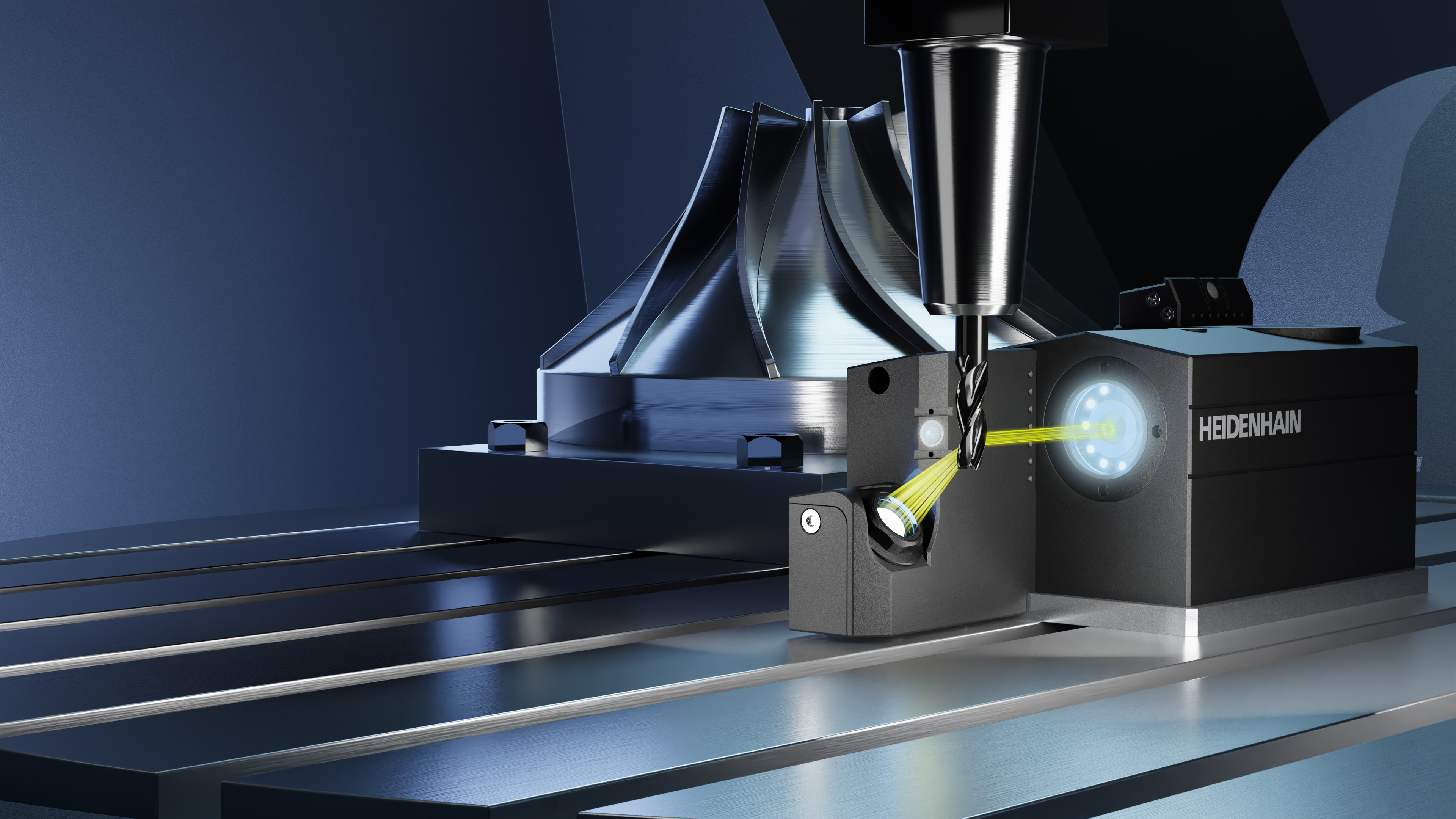

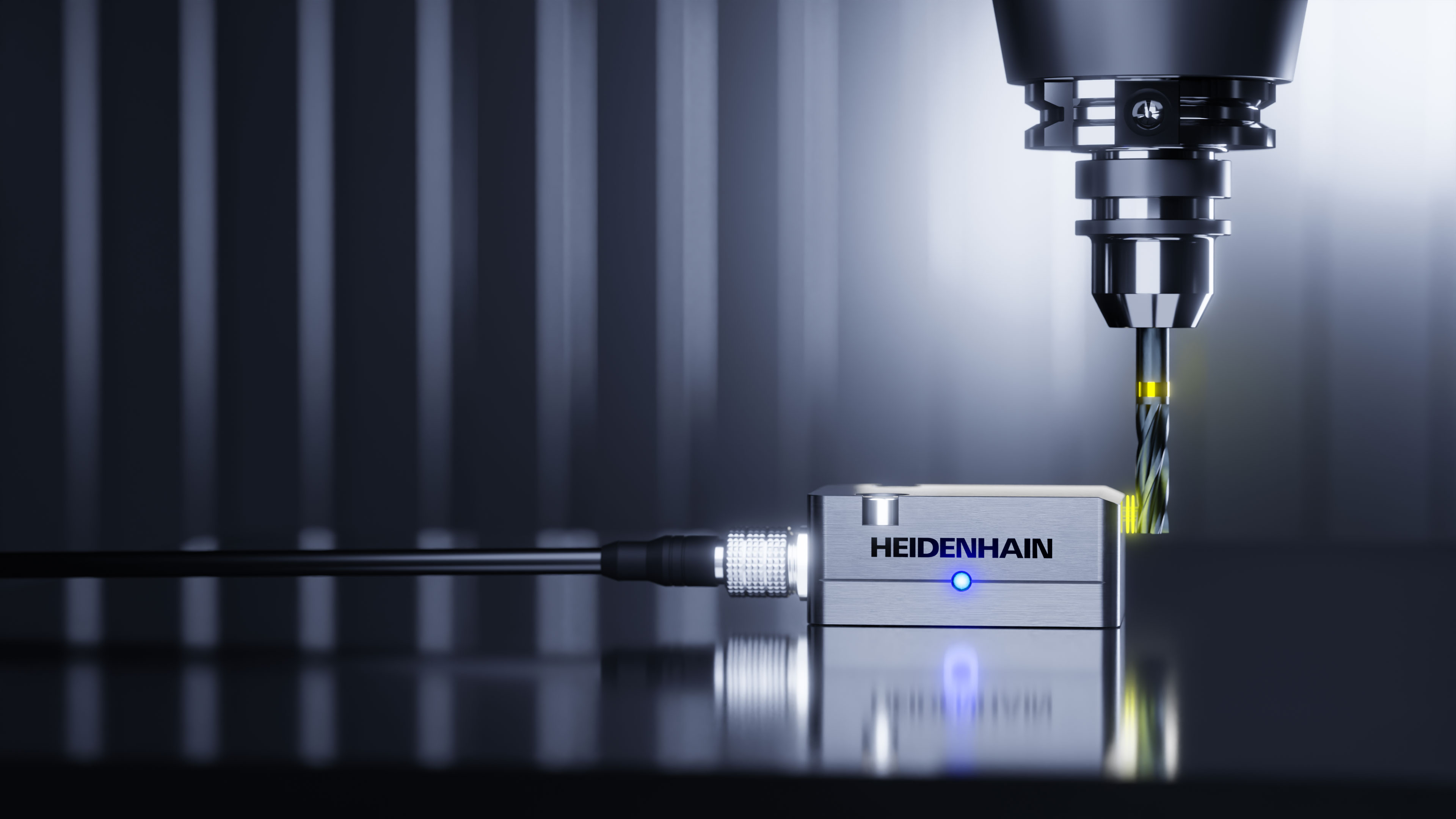

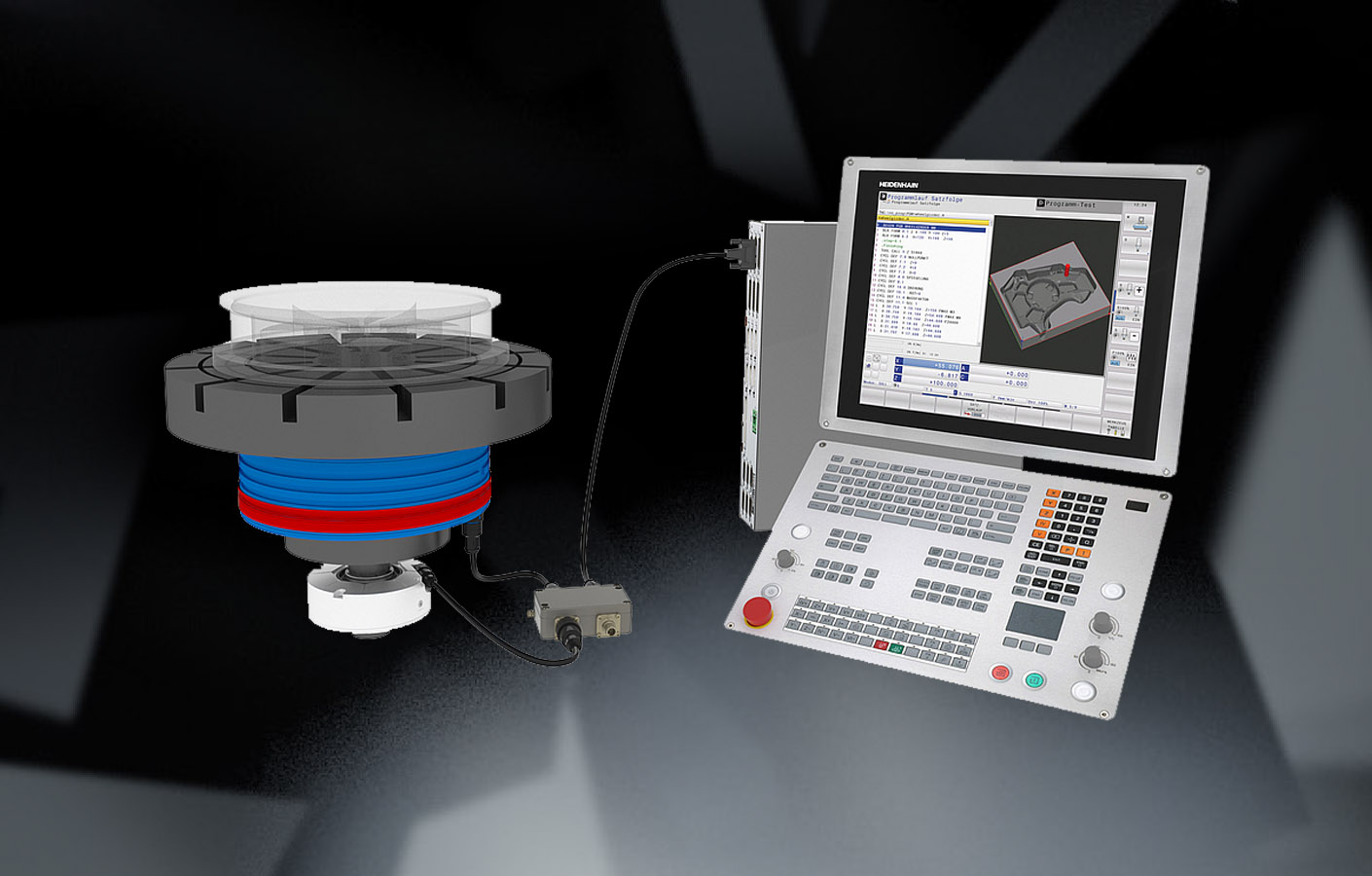

Visual Tool Check 1.6:

AI-driven flank wear measurement

Created for the VT 122 camera, the new Visual Tool Check software version 1.6 will enable AI-driven flank wear measurement, thereby automating manual inspection work while enabling faster process documentation in industries such as aerospace and medical tech. The VT 122 camera and Visual Tool Check software are a time-saving solution for holistic tool monitoring.

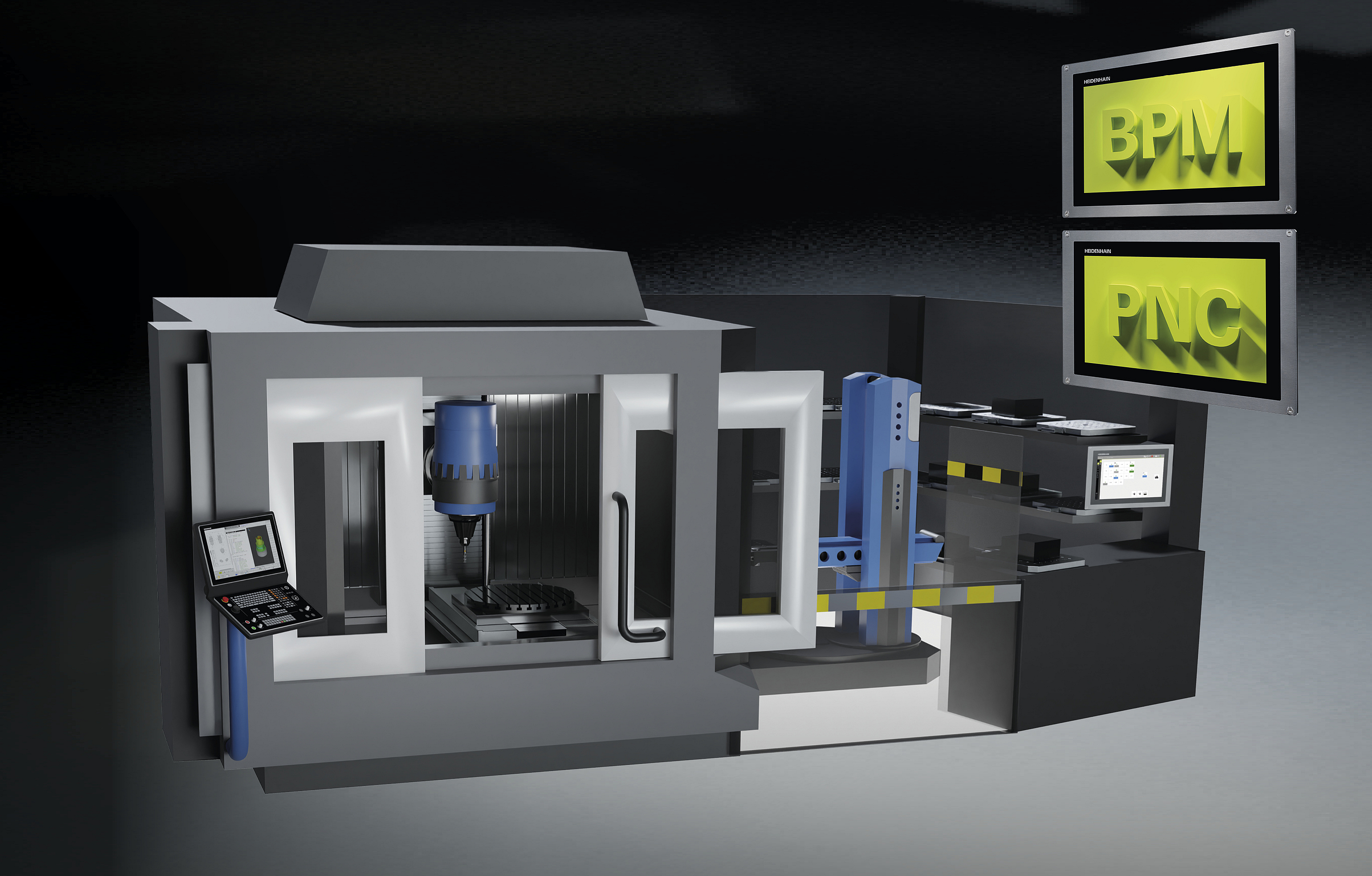

Speak to your robot in KLARTEXT

Automated machine tools with a pallet system and a machine-tending robot have become an essential capital asset on shop floors. But the robot and machine tool are separate systems requiring different programming languages and often two experts familiar with them. Until now!

HEIDENHAIN has found a way to make robots understand Klartext. Users of HEIDENHAIN TNC controls can program machine-tending robots from within the TNC user interface by teaching-in the desired movements and saving them as Klartext code in the NC program. This saves time and enables more versatile automation during machine setup. Find out more in our video.