Virtual trade show

|

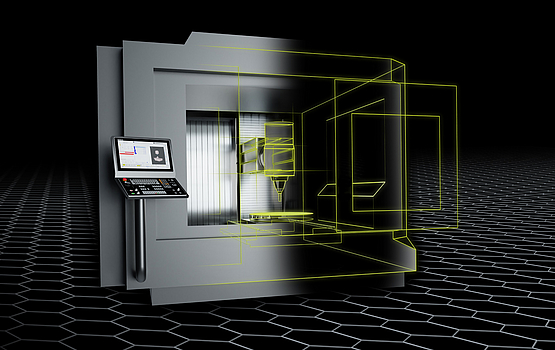

Machine tool

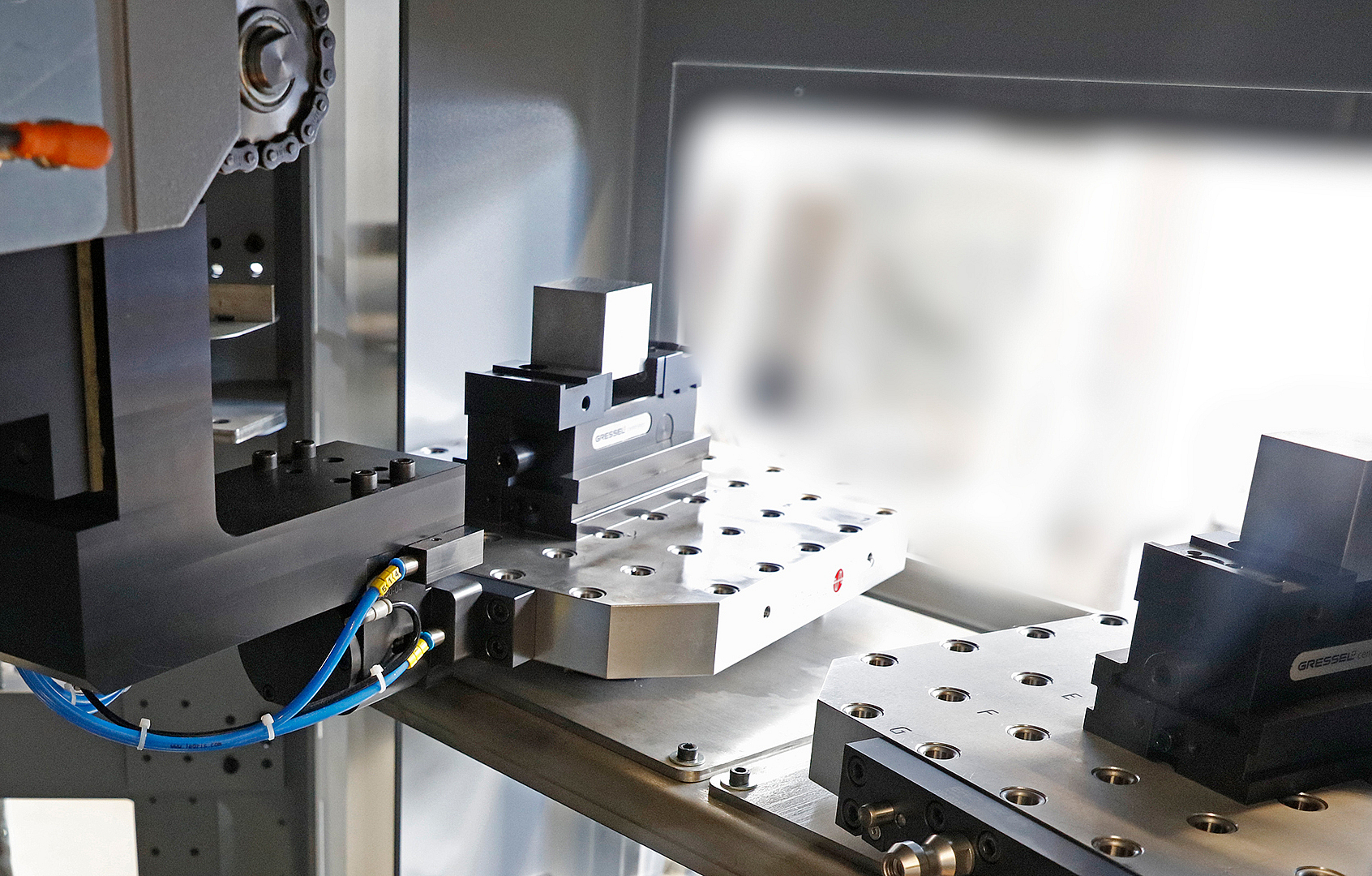

For automated equipment operators

- Work flexibly with Remote Desktop Manager on the PNC 610.

- Remotely operate the machine and automated equipment controls.

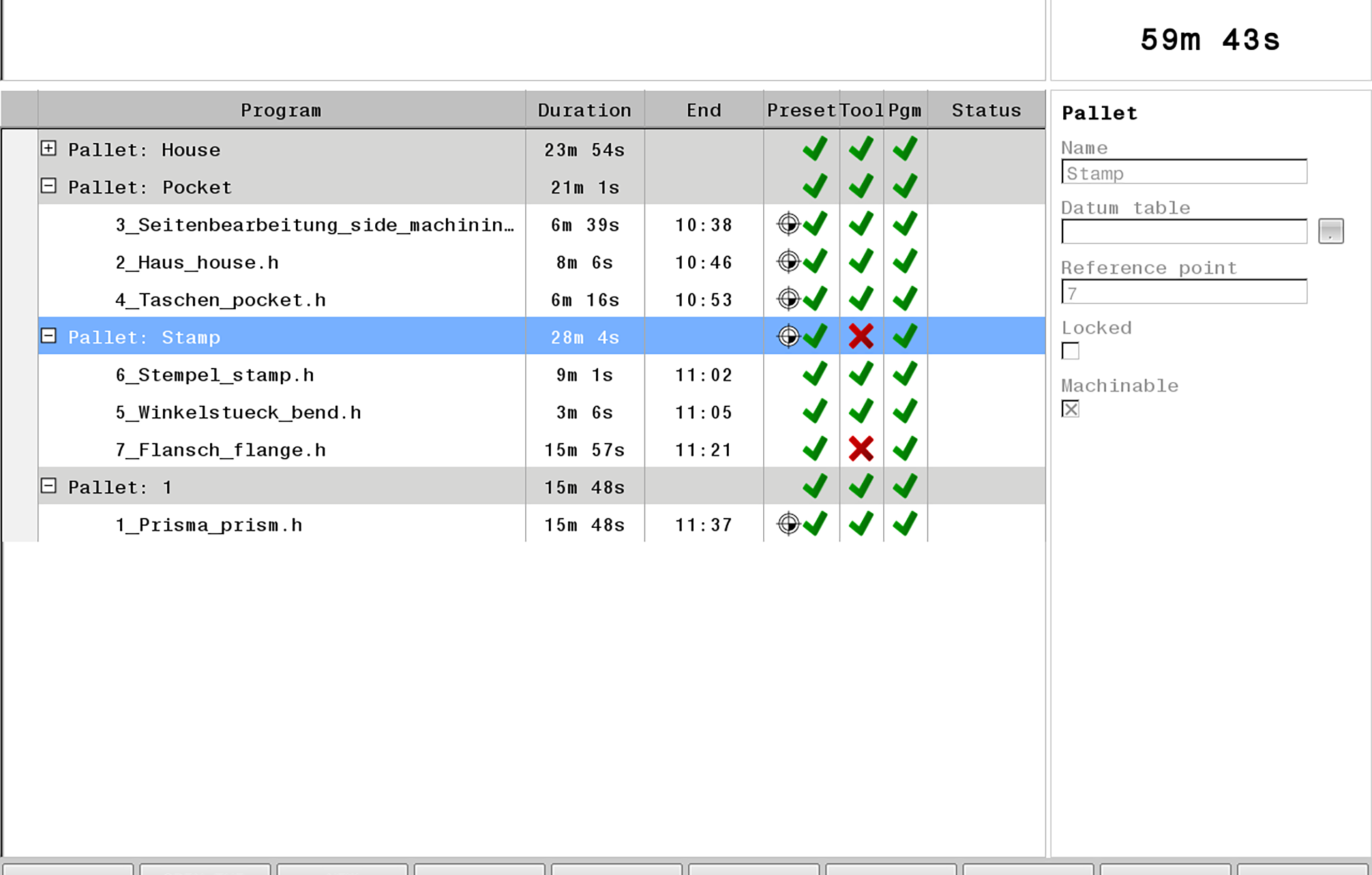

- Reliably plan machining sequences in advance with Batch Process Manager.

- Easily react to changes in the work sequence.

- Benefit from maximum compatibility with the TNC control.

For machine manufacturers and automation providers

- Benefit from hardware already being used in milling and turning machines.

- Draw directly on services from HEIDENHAIN during software development.

- Freely program your equipment communication and graphical user interface with Python.

- Readily retrofit prepared machines.

- Use familiar PC tools for development and servicing.