Empower Productivity

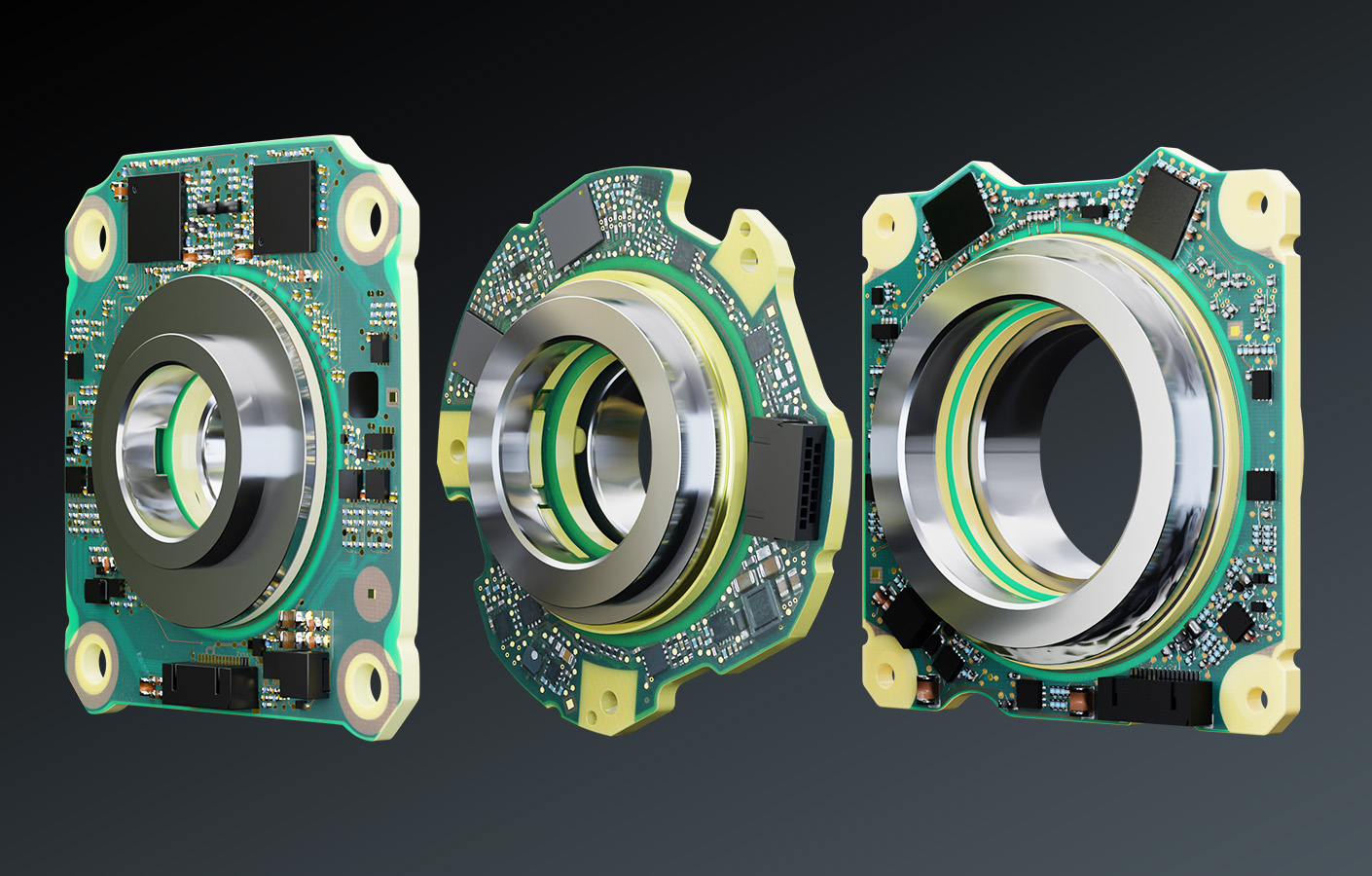

The right encoders for every robotics and automation challenge

The HEIDENHAIN GROUP is your one-stop provider for rotary encoders, angle encoders, and linear encoders for the full range of standard to high-end applications.

Improve the productivity, reliability, and accuracy of your machines with motion-feedback solutions from HEIDENHAIN, AMO, RENCO, and RSF.

More solutions with special features

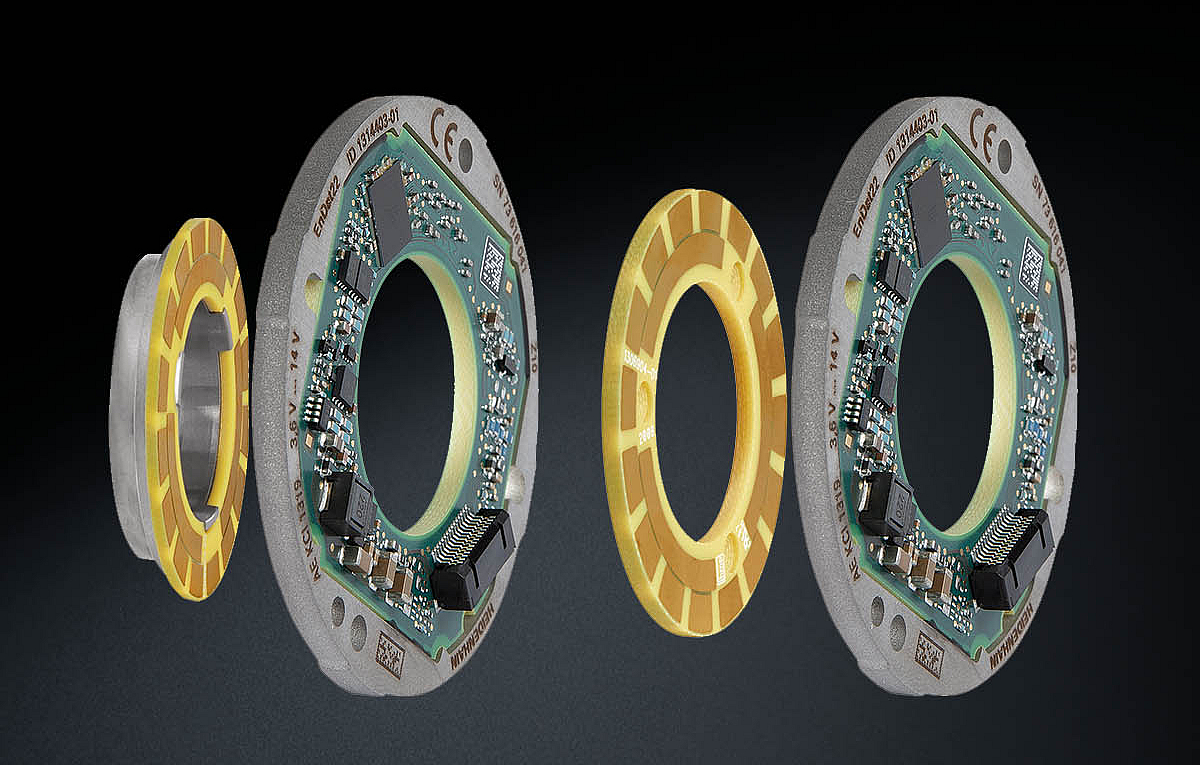

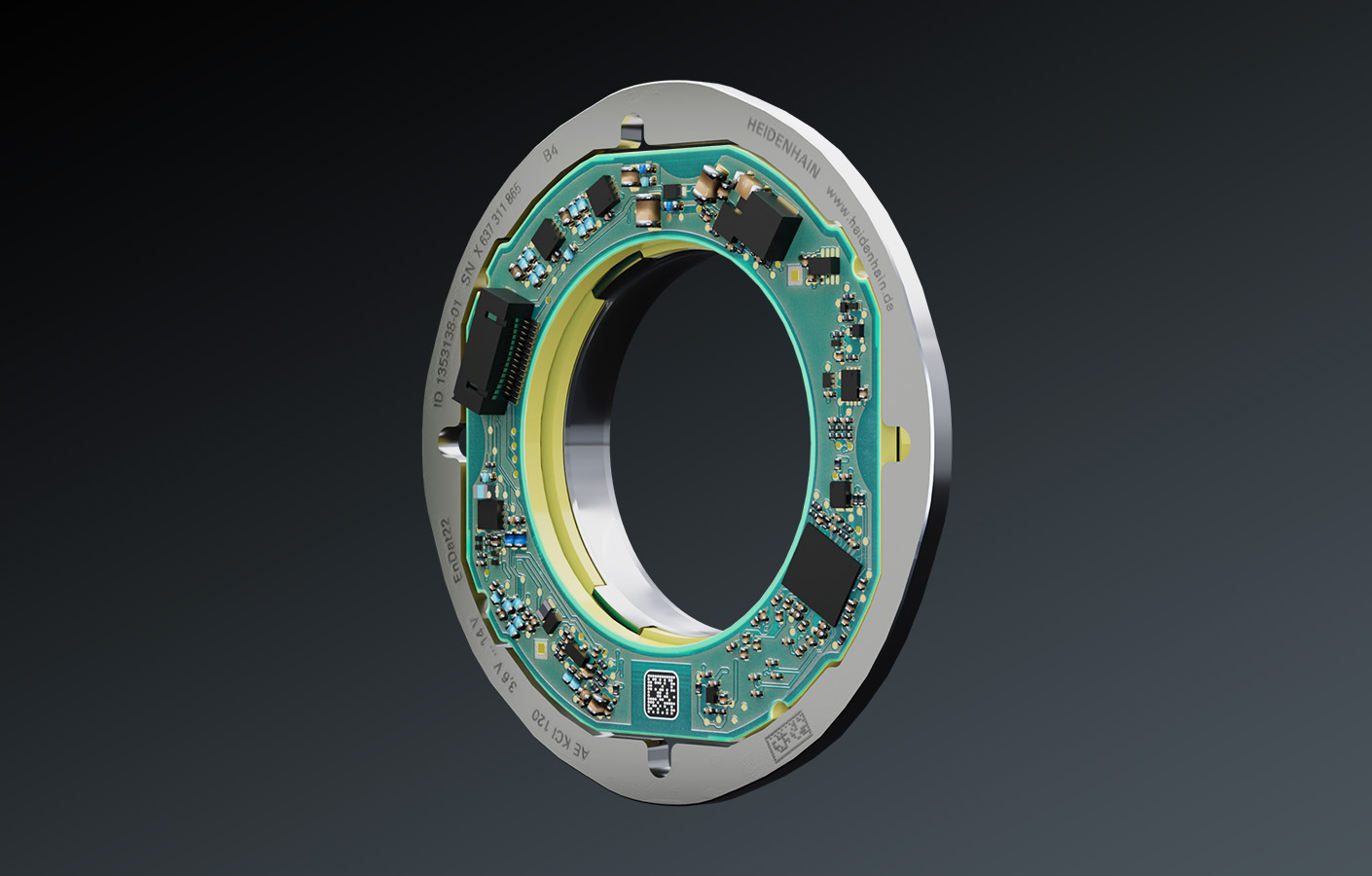

Their special characteristics make them ideal for robotics: explore the many robot-suitable encoders and system solutions from HEIDENHAIN and its brands AMO, RENCO, and RSF. These include a rotary encoder for press-fit mounting on small motors, as well as the EnDat 3 interface with bus operation, enabling the integration of multiple encoders within your system. Find out more about these and other exciting products and technologies:

Empower Productivity

The right encoders for every robotics and automation challenge

The HEIDENHAIN GROUP is your one-stop provider for rotary encoders, angle encoders, and linear encoders for the full range of standard to high-end applications.

Improve the productivity, reliability, and accuracy of your machines with motion-feedback solutions from HEIDENHAIN, AMO, RENCO, and RSF.