HEIDENHAIN at EMO 2025: Empower manufacturing

Intelligent system solutions for machine tools and automated manufacturing processes

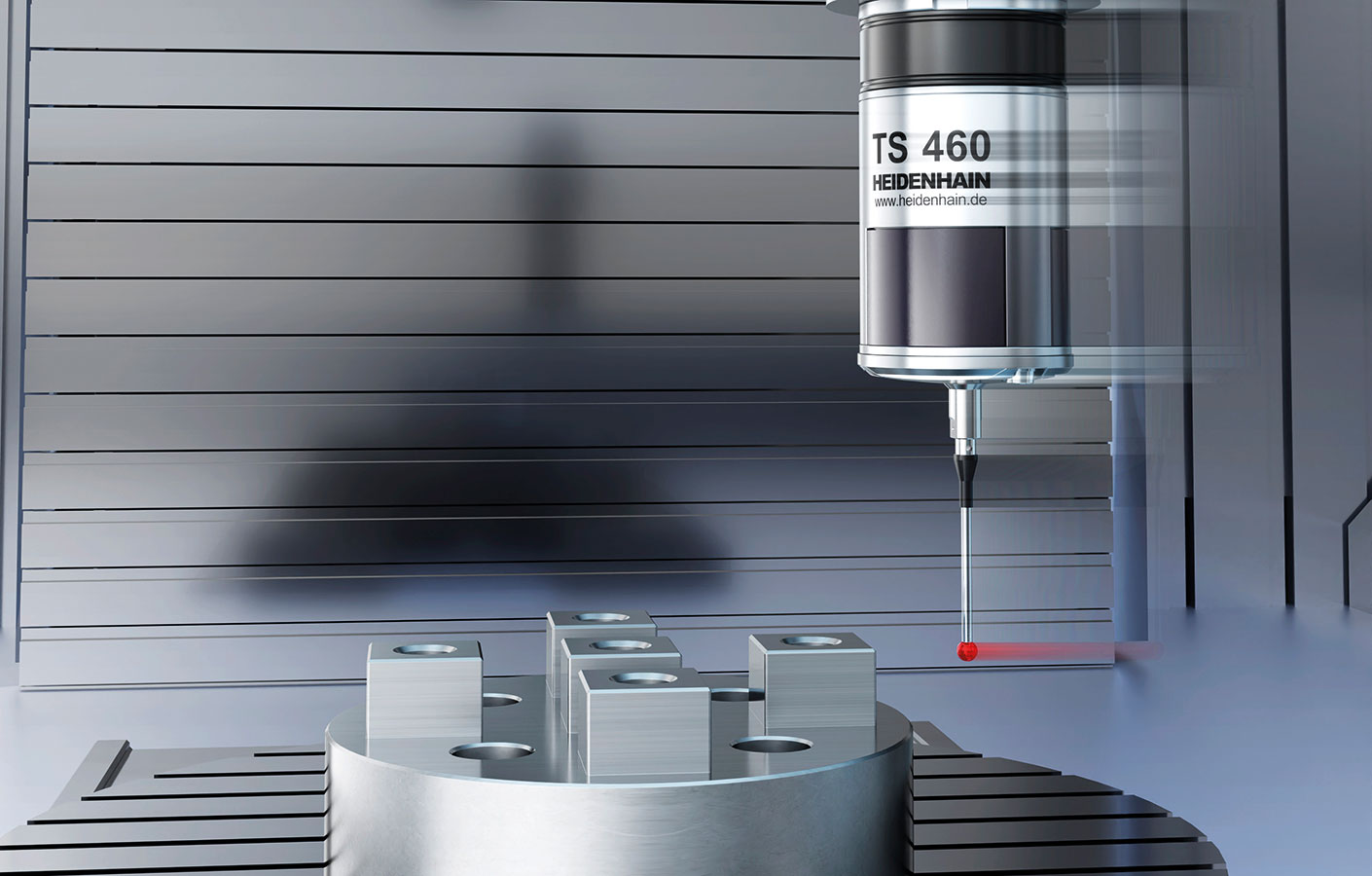

Experience exceptional accuracy, reliability and performance through rigorously engineered systems and seamlessly integrated components from the HEIDENHAIN GROUP.

Partner with us to make your manufacturing more efficient, agile and future-ready.

HEIDENHAIN main exhibit: Hall 6, Booth F45 | TNC Club Lounge: Hall 6, Booth F55

A perfect combination: The TD 110, TNC7 and StateMonitor software

Respond faster to broken tools with the combined functionality of the TD 110 tool breakage detector, the TNC7’s tool inspection cycle and StateMonitor’s Messenger function.

The TD 110 inductive tool breakage detector

Pass the tool by the detector to increase process reliability and reduce non-productive time during inspection while the spindle is rotating at operational speed.