Virtual trade show

|

Machine tool

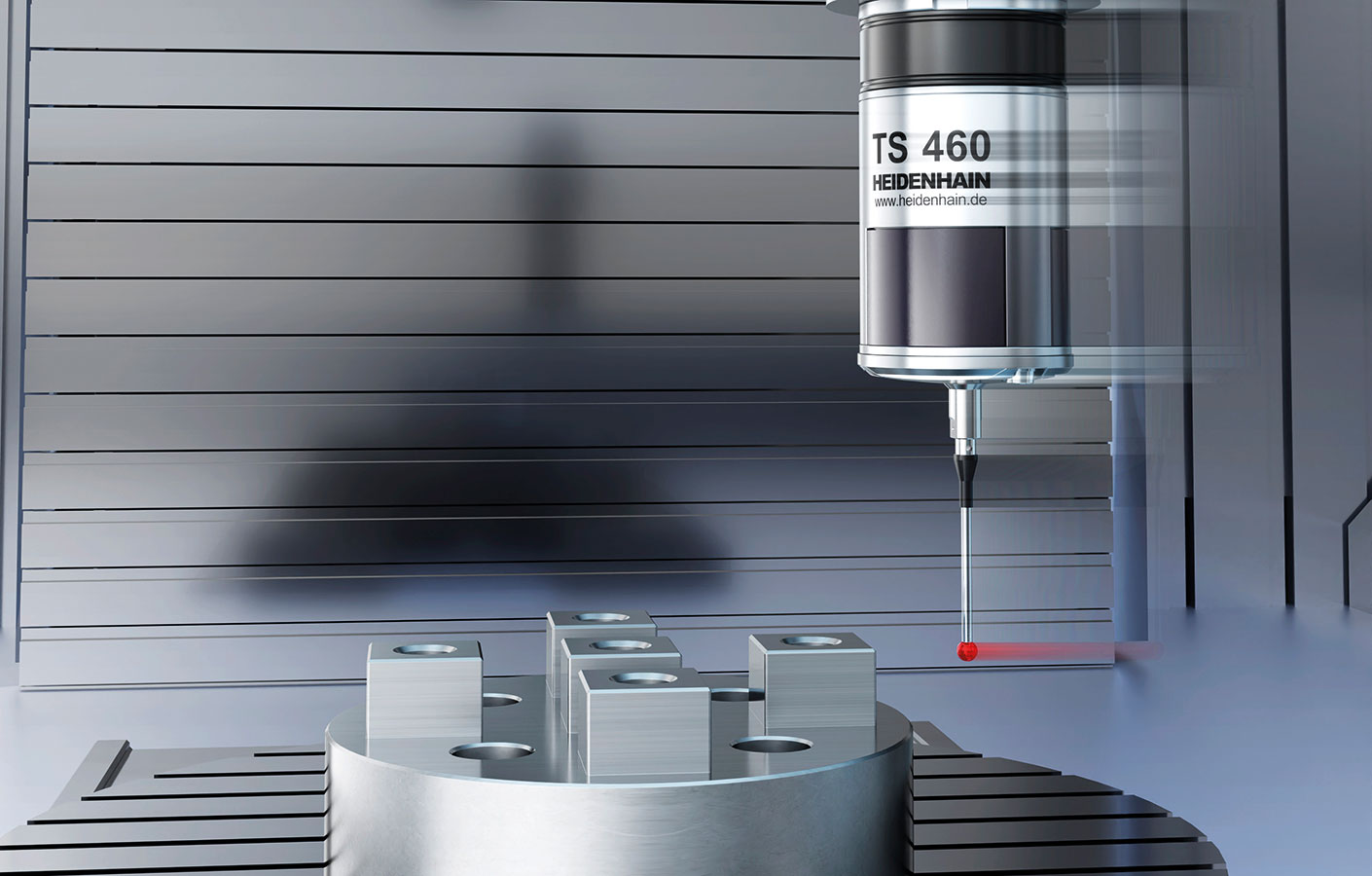

A perfect combination: The TD 110, TNC7 and StateMonitor software

Respond faster to broken tools with the combined functionality of the TD 110 tool breakage detector, the TNC7’s tool inspection cycle and StateMonitor’s Messenger function.

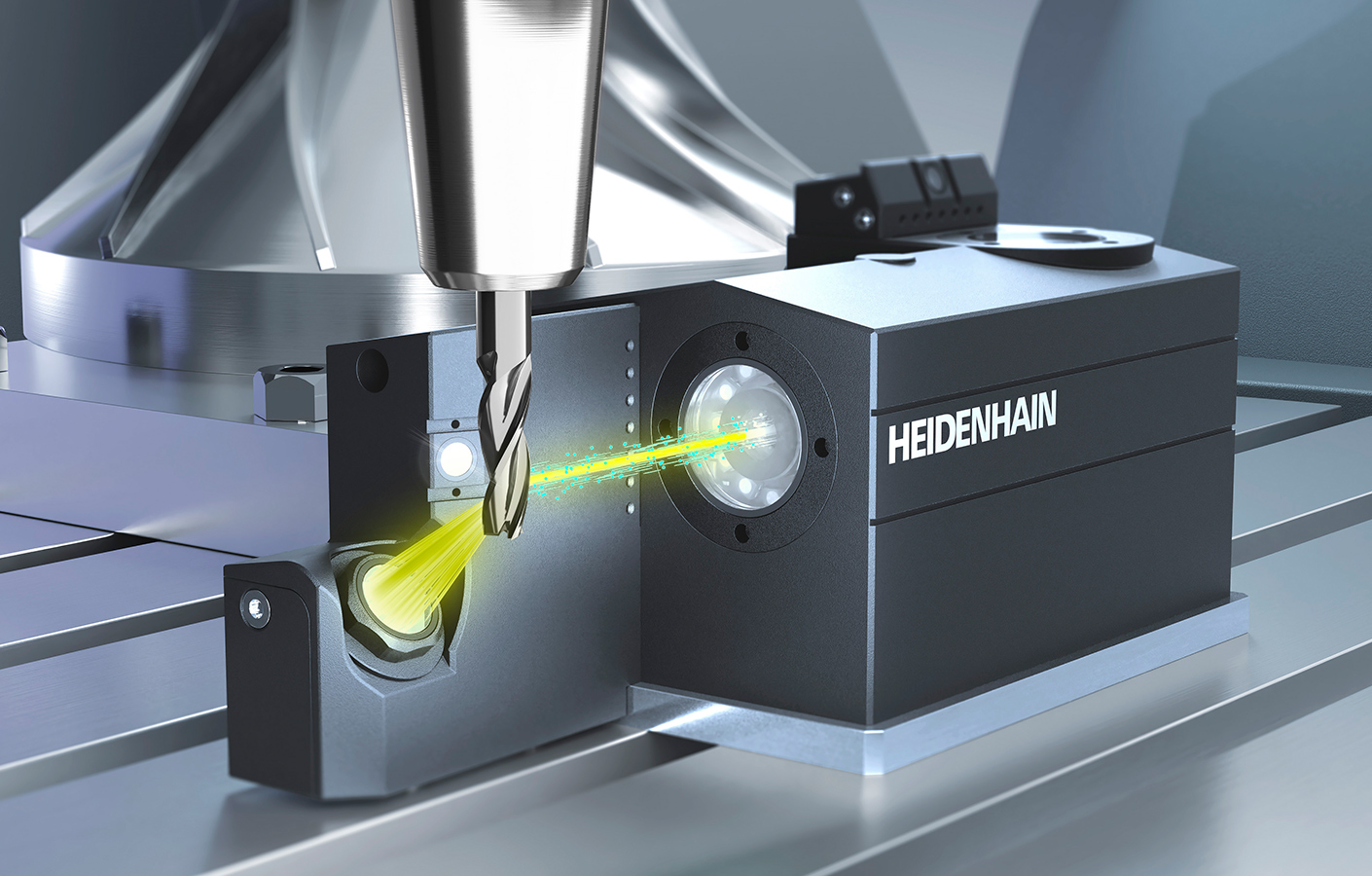

The TD 110 inductive tool breakage detector

Pass the tool by the detector to increase process reliability and reduce non-productive time during inspection while the spindle is rotating at operational speed.